High-strength steel refers to steel with a tensile strength of 785MPa or more. It has high strength, hardness, and toughness, and is widely used in construction, bridges, automobiles, aerospace, military, and other fields. However, during the production and processing of high-strength steel, stress can be generated due to various reasons, leading to deformation, warping, and other issues that can affect the quality and service life of the product. Therefore, a series of measures need to be taken to remove stress, and precision leveling machines are a very effective method.

1. Characteristics of high-strength steel

High-strength steel has high strength and hardness, and at the same time, its toughness and plasticity need to be good during use. Therefore, the production and processing of high-strength steel are very important. The production process of high-strength steel requires multiple cold-working, hot-working, and welding processes, all of which can cause stress in high-strength steel, leading to plate deformation, warping, and other issues.

2. Causes of stress generation

There are many reasons why high-strength steel produces stress, mainly including the following:

(1) During cold working, due to the high strength and hardness of high-strength steel, bending, stretching, and other deformation are easily generated, resulting in internal stress.

(2) During hot working, high-strength steel will experience thermal stress during heating and cooling, causing plate deformation.

(3) During welding, the welding joint of high-strength steel will generate thermal stress and residual stress, which will affect the plate.

3. Working principle of precision leveling machine

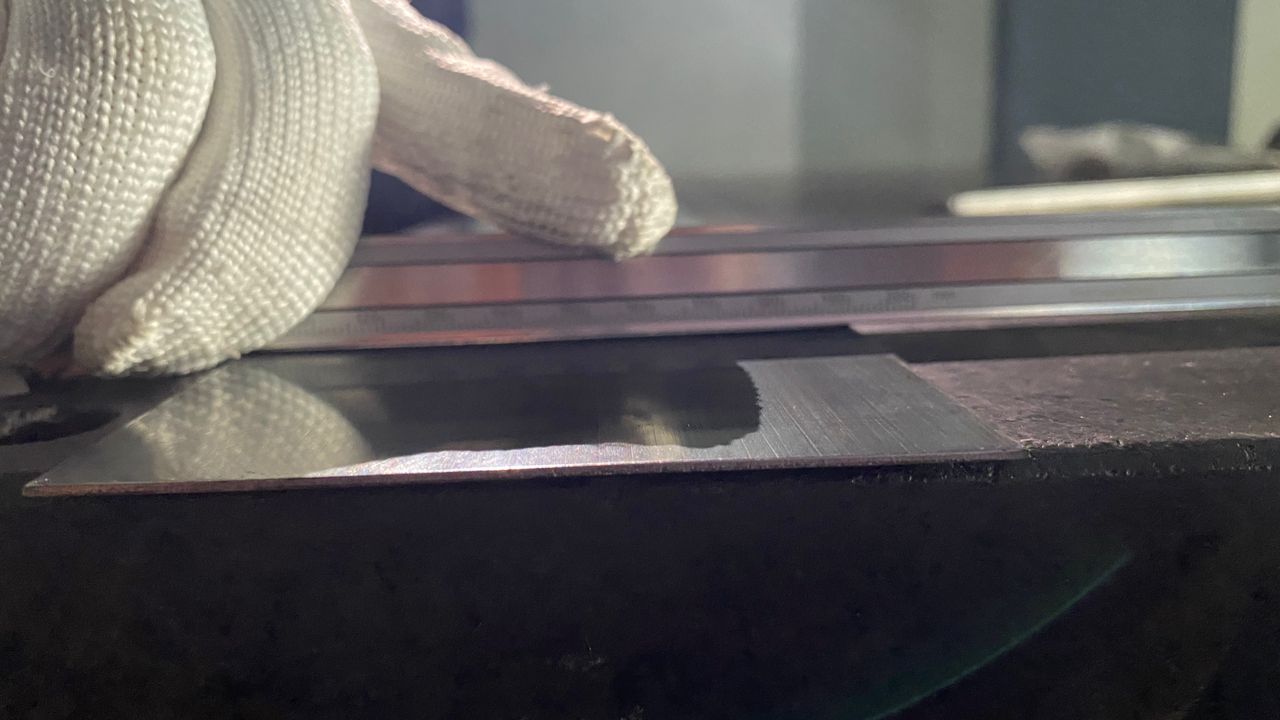

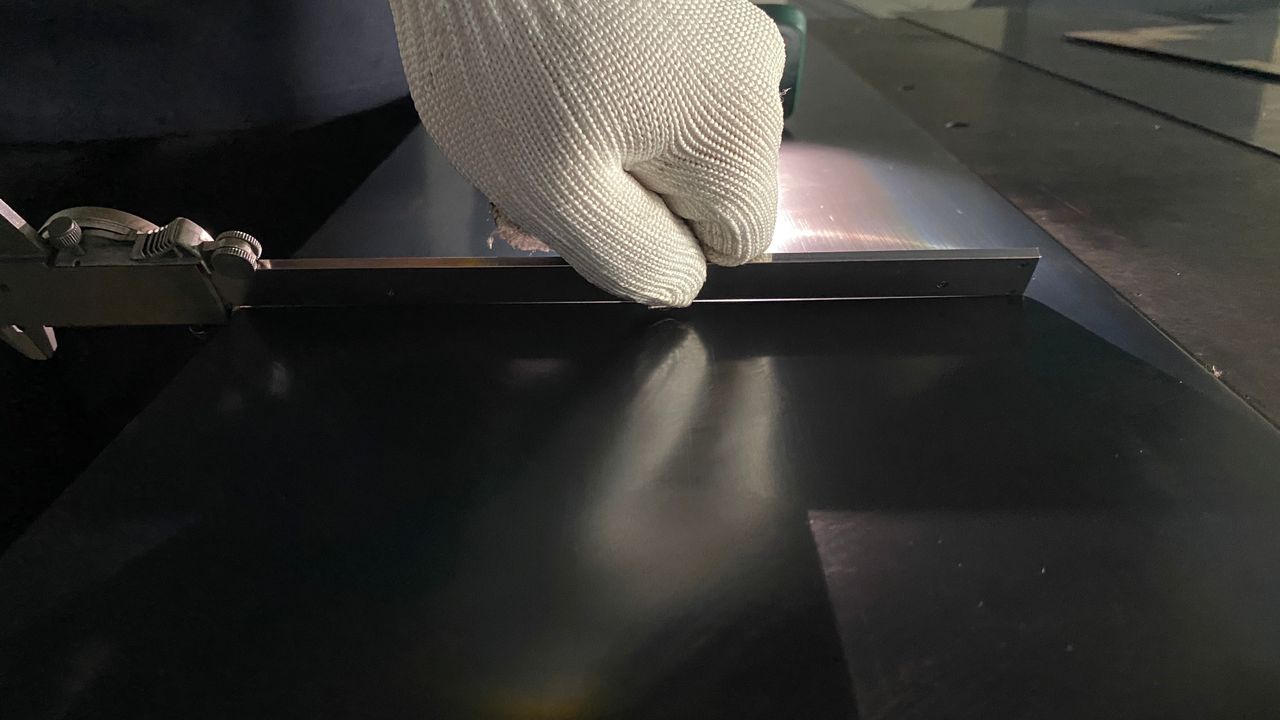

A precision leveling machine is a device specifically used to remove residual stress in metal plates and restore them to a flat state. Its main working principle is to remove stress in the plate by applying reverse stress, thereby restoring the original flat state of the plate.

(1) Hydraulic system: The precision leveling machine mainly applies pressure through a press and hydraulic system to remove residual stress in the metal plate. The hydraulic system consists of a press, a working oil cylinder, an oil pump, an oil tank, oil pipes, and other components. The press applies pressure and pushes hydraulic oil into the oil cylinder, causing the piston inside the oil cylinder to move upward and apply reverse stress.

(2) Frame: The frame of the precision leveling machine is the support structure of the entire device, which has high rigidity and stability and can withstand a lot of pressure and vibration.

(3) Coil loading device: The coil loading device is an important component of the precision leveling machine, which mainly feeds the metal plate into the machine for leveling. The coil loading device usually consists of a feeder, rollers, and adjustment devices, which can be adjusted according to different plate thicknesses and widths.

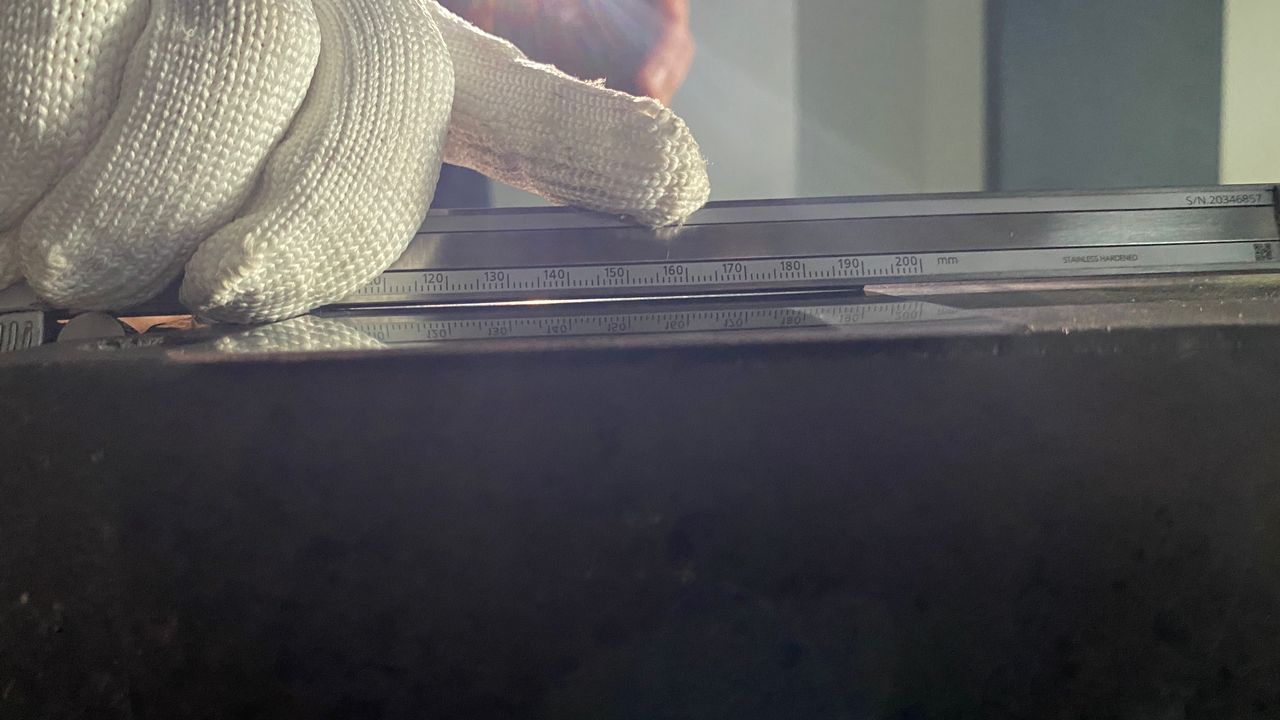

(4) Guide rail: The guide rail is an important component of the precision leveling machine, which mainly ensures the stability and accuracy of the coil loading device. The guide rail usually uses linear guides and rolling guides, and has high precision and stability.

(5) Pressure rod: The pressure rod is an important component of the precision leveling machine, which mainly applies pressure to the coil loading device, applies reverse stress, and restores the flat state of the plate. The pressure rod usually uses hydraulic or mechanical drive and has high precision and stability.

4. Advantages of precision leveling machine

Compared with other methods of removing stress, precision leveling machine has the following advantages:

(1) High leveling efficiency: The precision leveling machine can quickly remove residual stress in the metal plate and restore the flat state, improving production efficiency.

(2) High precision: The precision leveling machine has high precision and stability, which can ensure the flatness and surface quality of the plate.

(3) Simple operation: The precision leveling machine is easy to operate, and only needs to follow the operation process.

(4) Wide leveling range: The precision leveling machine can be applied to leveling various metal plates, including high-strength steel, stainless steel, aluminum alloy, etc.

5. Conclusion

As an important structural material, high-strength steel can generate stress during production and processing, affecting the quality and service life of the product. Precision leveling machine is a very effective method of removing stress, which can quickly remove residual stress in the metal plate and restore the flat state, improving production efficiency and product quality. Therefore, the use of precision leveling machines is necessary in the production and processing of high-strength steel.