Why Level

1.Defects in internal stress and flatness of plates and sheet metal parts

Causes of internal stress and flatness defects in the plate:

Residual stress formed during material manufacturing

Mechanical cutting or thermal cutting

temperature change

These internal stress and flatness defects will have adverse effects on subsequent processing.

2. Internal stress and flatness defects in the coil

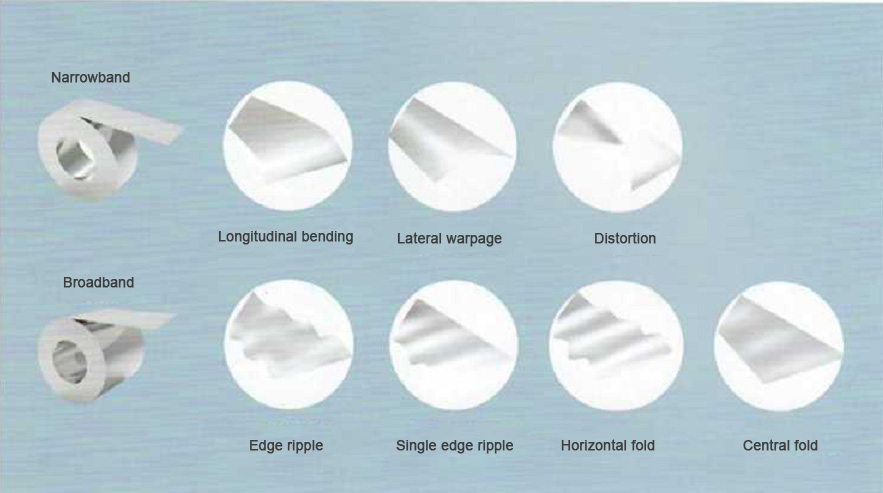

Typical situation of uneven coil

The most common flatness defects of coils are longitudinal curling and lateral warping. Usually, the defective problem of the coil is caused by the rolling process during material manufacturing or the subsequent cutting process. Longitudinal curling is caused by plastic deformation during winding. Lateral warpage is caused by uneven cooling or longitudinal slitting of the rolled material over the entire width of the coil (residual stress).

3 the problems that will occur during processing of unleveled plates

Bend

There will be angular deviations during bending, which will increase the rework rate and scrap rate.

welding

Usually, the welding preparation for unleveled materials is very cumbersome. If a welding robot is used for operation, this will also reduce the processing safety, and the welding time will be longer, which will eventually lead to an increase in processing costs and increase in temperature changes. The result of the temperature change is that the internal stress in the material is released so that the material will be deformed. This can lead to rework and make production operations longer.

4. the problems that will occur during the processing of unleveled coils

stamping

Flatness defects and internal stress in the coil can make precise forming processing difficult. On the one hand, it may cause damage to the mold, on the other hand, it may cause the quality of the finished product to decrease. Moreover, the flatness defects of the raw materials may also cause the entire equipment to stop operating, reducing the efficiency of the equipment.

Shears

The shearing process will release the stress in the raw material, and the deformation of the material will be visible to the naked eye. The flatness defect of the coil will make the cutting accuracy not guaranteed. The flatness of the raw material is a very important quality criterion, because usually the sheared sheet material must continue to be processed in the subsequent process.

Roll forming

During roll forming, rollers are used to change the shape of the steel plate coil through a series of processing steps. The stress and flatness of the raw material make it difficult to achieve precise forming of the coil. Due to the fast processing speed, the flatness defects of the coil will have a serious negative impact on the processing safety of the roll forming line.

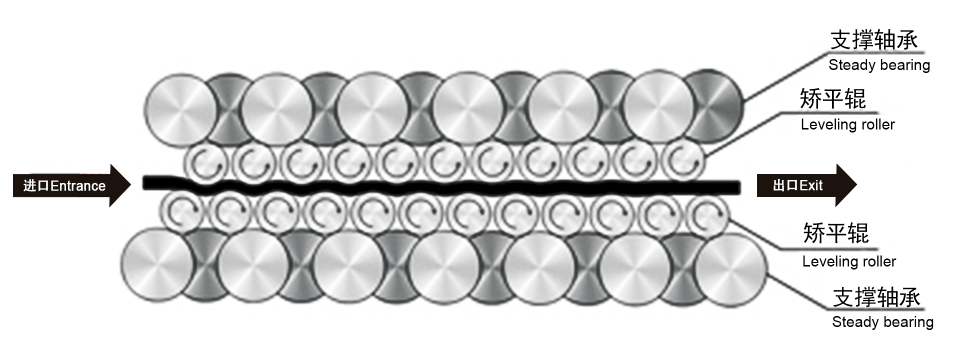

Summary: The internal stress and flatness defects of the plates and coils will ultimately be leveled and optimized by the roller leveler. The precision leveling machine uses the "Bauschinger effect" of the material to repeatedly bend the plate, gradually reducing the bending deflection, so that the multiple original curvatures gradually become a single curvature, and finally they are leveled to meet the process requirements The leveling accuracy simplifies the convenient subsequent processing procedures.

Summary: The internal stress and flatness defects of the plates and coils will ultimately be leveled and optimized by the roller leveler. The precision leveling machine uses the "Bauschinger effect" of the material to repeatedly bend the plate, gradually reducing the bending deflection, so that the multiple original curvatures gradually become a single curvature, and finally they are leveled to meet the process requirements The leveling accuracy simplifies the convenient subsequent processing procedures.