A plate leveler machine for high-strength plates is a specialized piece of equipment used in the metal industry to straighten and flatten high-strength steel plates. These plates are known for their superior strength and durability, making them ideal for applications where structural integrity is crucial, such as in the construction, shipbuilding, and heavy machinery industries. In this article, we will explore the importance of plate leveler machines for high-strength plates and their specific features.

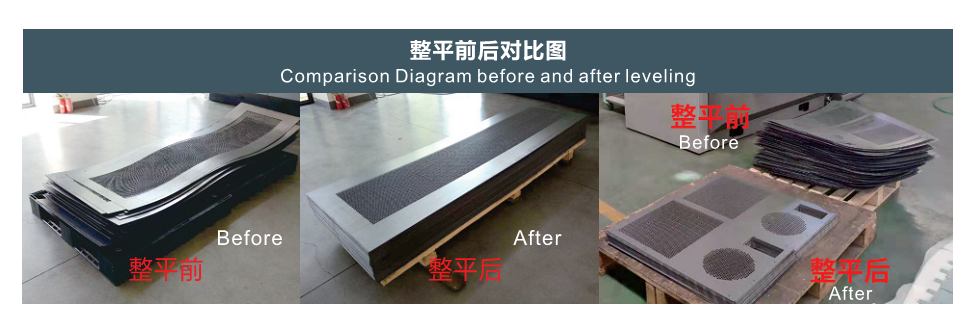

High-strength plates are often subjected to various manufacturing processes, such as rolling or heat treatment, which can introduce deformations and unevenness. These imperfections need to be corrected to ensure that the plates meet the required flatness and dimensional tolerances. This is where plate leveler machines come into play. These machines are designed to remove any distortions or warpage in the plates, resulting in flat and straightened surfaces.

One of the key benefits of using a plate leveler machine for high-strength plates is the improvement in the overall quality of the plates. By straightening the plates, these machines ensure that the final product is free from any distortions or surface irregularities. This is important for applications where precise alignment and fit are necessary, such as in the construction of bridges or offshore structures.

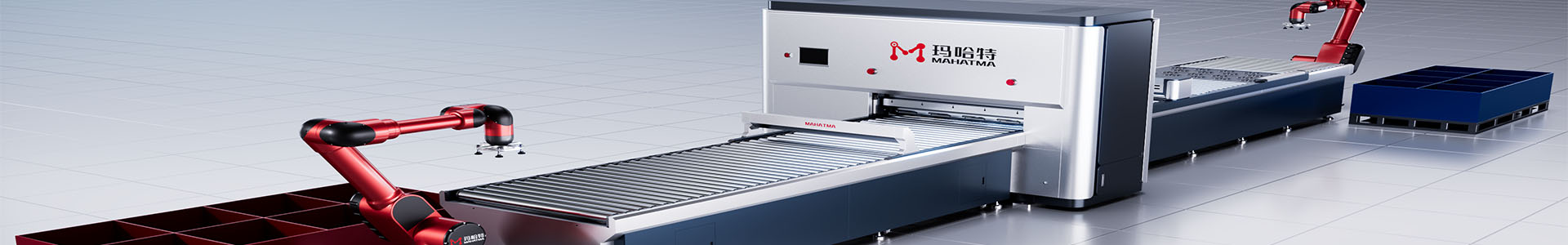

Another advantage of plate leveler machines is their ability to handle high-strength plates with different thicknesses and widths. These machines are equipped with adjustable leveling rolls or hydraulic cylinders that apply pressure to the plates, gradually straightening them as they pass through the machine. The number and arrangement of these rolls can be customized to accommodate plates of various sizes and configurations.

Plate leveler machines for high-strength plates are also designed to provide precise and consistent leveling results. They are often equipped with advanced control systems that allow operators to adjust the pressure and gap between the leveling rolls, ensuring optimal straightening performance. Additionally, these machines may have automatic thickness and crown control features, which further enhance the accuracy and efficiency of the leveling process.

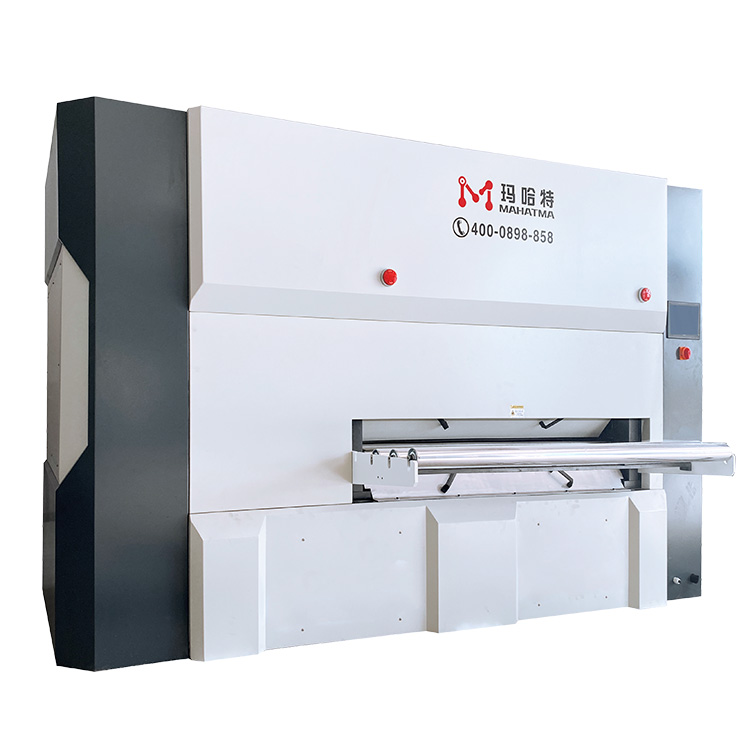

Furthermore, plate leveler machines are built to withstand the heavy-duty demands of processing high-strength plates. They are typically constructed with robust frames and heavy-duty components, ensuring long-term durability and reliability. Additionally, these machines may have features such as automatic lubrication systems and overload protection, which contribute to their overall performance and safety.

A plate leveler machine for high-strength plates is an essential piece of equipment in the metal industry for achieving flat and straight surfaces. These machines offer numerous benefits, including improved product quality, precise leveling results, and versatility in handling plates of different sizes. With their advanced features and heavy-duty construction, plate leveler machines are capable of meeting the demanding requirements of processing high-strength plates. As the demand for high-strength materials continues to rise, these machines will play a crucial role in ensuring the quality and integrity of the final products.

Product Overviews