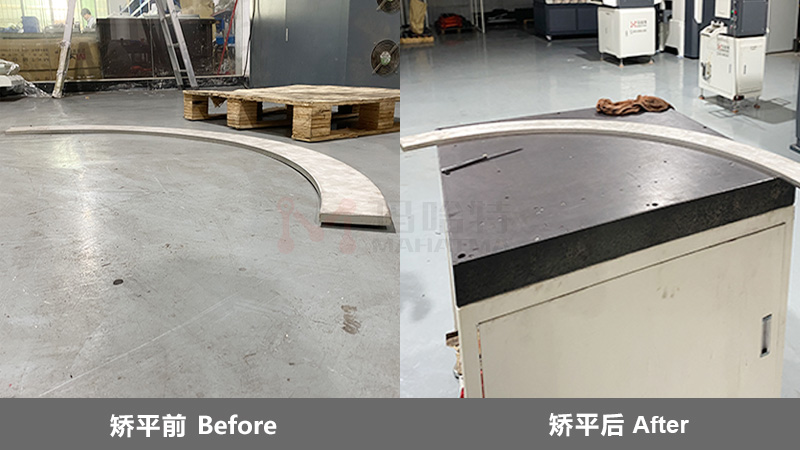

It only takes more than ten seconds to go through it on the Mahat leveler, and the tolerance drops to less than 10 wires in an instant, and the processing efficiency is rapidly improved. The Mahat leveler in the steel production workshop works 5-6 hours a day, and is responsible for leveling 235 steel plates, stainless steel plates, high-strength steel plates, and laser-cut workpieces with a thickness of 0.6mm-15mm. What precision leveling needs to achieve is not only the flatness of the sheet, but the removal of the internal stress of the material is the core.

Benefits to customers: All parts must be leveled after laser cutting and deburring, even if the customer does not require, "This is not only a good experience for customers, but also for the long-term interests of customers - In fact, after leveling through the leveling machine, the overall cost of production will be reduced a lot."

The customer said: "Precision leveling needs to achieve not only the flatness of the plate, but also the removal of the internal stress of the material is the core. In the field of precision leveling,