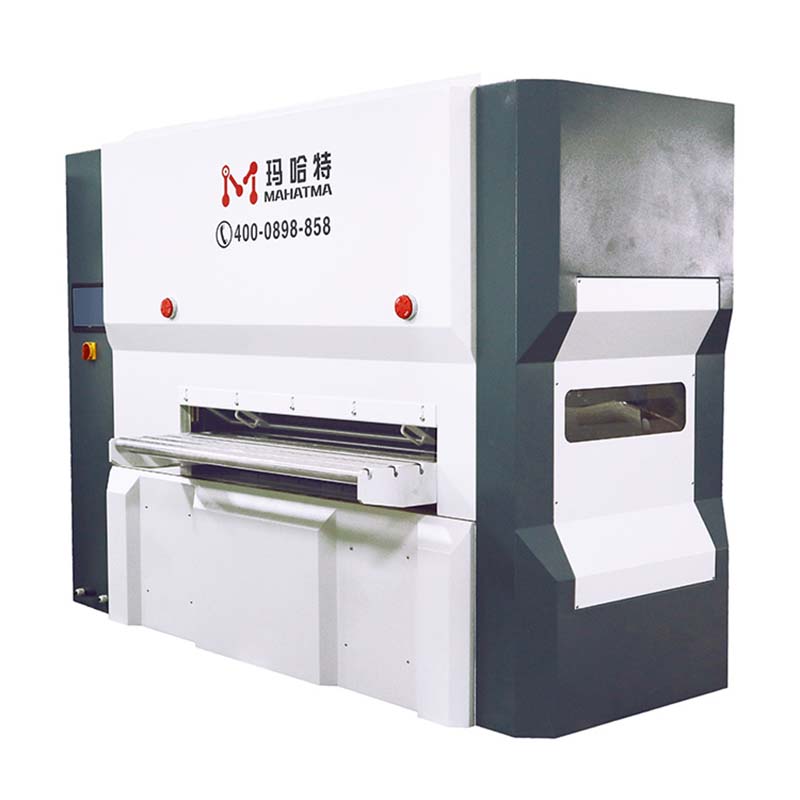

Laser cutting is a widely used technology in the manufacturing industry for precise and efficient cutting of various materials. However, the process of laser cutting can sometimes lead to the deformation of the cut parts due to the intense heat generated during the cutting process. These deformations can affect the overall quality and dimensional accuracy of the parts, making them unsuitable for use in the final product. To overcome this challenge, a straightening machine for laser cutting parts has been developed.

It aims to provide a comprehensive overview of the straightening machine, its functions, working principles, and advantages. By understanding the capabilities of this machine, manufacturers can enhance the quality of their laser-cut parts, reduce waste, and improve overall production efficiency.

1. Importance of Straightening Machine for Laser Cutting Parts:

Laser cutting parts are often subjected to thermal stresses, resulting in distortions and deformations. These deformations can compromise the functionality and structural integrity of the parts. Therefore, it becomes crucial to invest in a straightening machine to rectify these distortions and ensure that the laser-cut parts meet the desired specifications.

2. Functions of Straightening Machine:

The primary function of a straightening machine for laser cutting parts is to correct the deformations caused during the cutting process. This machine uses various straightening techniques to restore the original shape and dimensions of the parts, ensuring their usability. It can handle a wide range of materials, including metals, plastics, and composites, making it a versatile solution for various industries.

3. Working Principles of Straightening Machine:

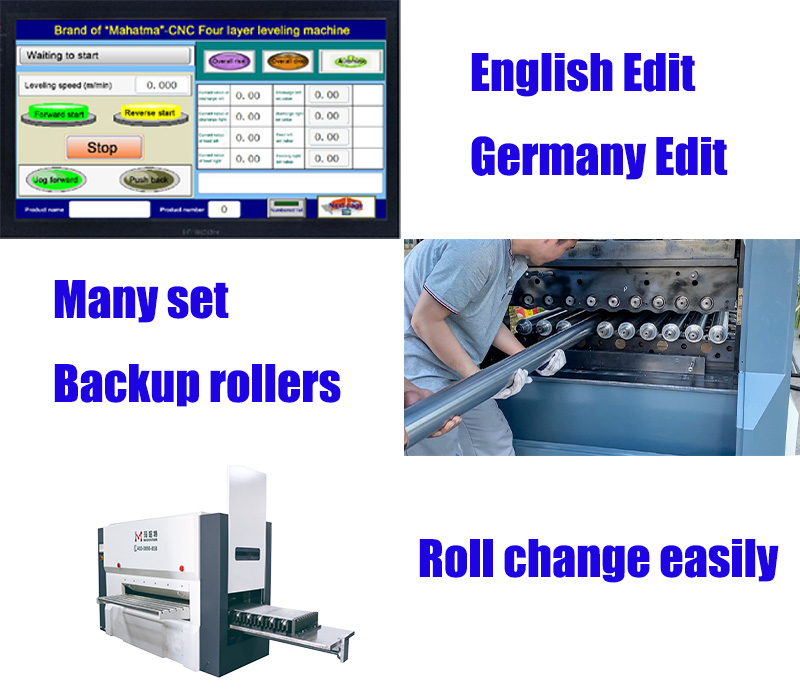

The straightening machine utilizes hydraulic or mechanical forces to apply controlled pressure on the deformed parts. It employs adjustable rollers or presses to gradually straighten the parts, carefully manipulating them until the desired shape is achieved. The process is typically automated, ensuring consistent and precise straightening results.

4. Advantages of Straightening Machine:

a) Enhanced Product Quality: By eliminating deformations, the straightening machine improves the dimensional accuracy and overall quality of the laser-cut parts. This ensures that the parts fit together seamlessly, reducing assembly issues and enhancing the performance of the final product.

b) Increased Production Efficiency: The straightening machine enables manufacturers to salvage deformed parts that would otherwise be discarded, reducing material waste and production costs. It also minimizes the need for manual labor, saving time and improving overall production efficiency.

c) Versatility: The straightening machine can handle various sizes and shapes of laser-cut parts, making it suitable for a wide range of applications. Its adjustable settings allow for customization, ensuring optimal straightening results for different materials and part geometries.

d) Cost-effective Solution: Investing in a straightening machine eliminates the need to outsource the straightening process, saving manufacturers significant costs in the long run. It also reduces the risk of rework or scrap parts, further improving cost-effectiveness.

The straightening machine for laser cutting parts is an essential tool for manufacturers looking to enhance the quality and accuracy of their laser-cut components. By eliminating deformations caused during the cutting process, this machine ensures that the parts meet the desired specifications, improving overall product quality and reducing waste. With its versatility, efficiency, and cost-effectiveness, the straightening machine is an invaluable asset in the manufacturing industry.

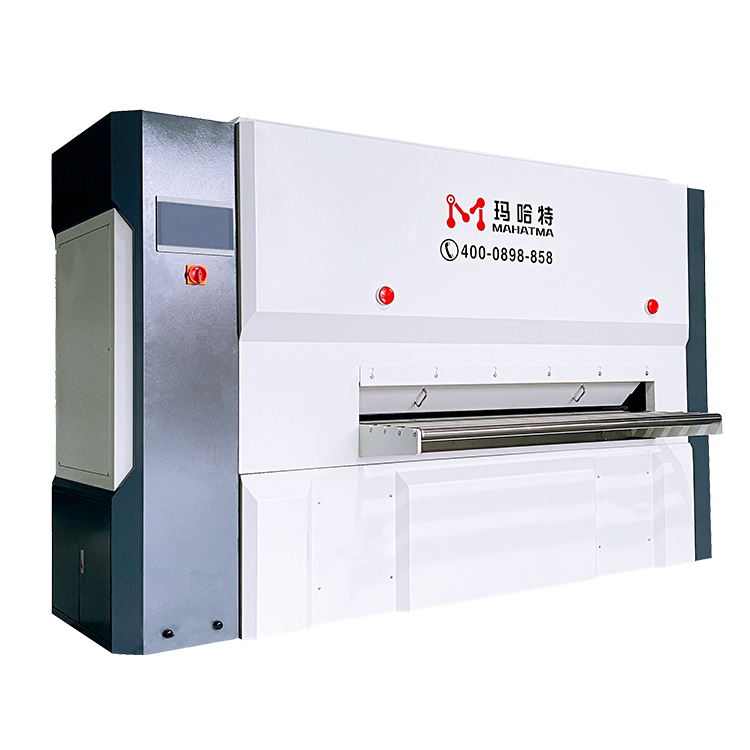

| Sheet Metal Straightening Machine Parameter Table |

| Machine Model | MHT30 | MHT40 | MHT50 | MHT60 |

| Roller Diameter | φ30mm | φ40mm | φ50mm | φ60mm |

| Roller Number | 21 | 21 | 19 | 19 |

| Speed | 0-10m/Min | 0-10m/Min | 0-10m/Min | 0-10m/Min |

| Leveled Width | <1600mm | <2500mm | <2500mm | <2100mm |

| Rated Plate Thickness | 0.5~2.0mm | 0.6~3.0mm | 0.8~4.0mm | 1.0~6.0mm |

| Maximum Thickness | 3 | 5 | 6 | 8 |

| Shortest Workpiece | 60mm | 70mm | 90mm | 100mm |

| Applicable Object | Laser cutting part, Punching & Perforated sheet |