Thick plate punching and flattening machine is a machine that flattens thick plates before and after punching. This type of machine is typically used in the metal processing industry to prepare metal plates for further processing.

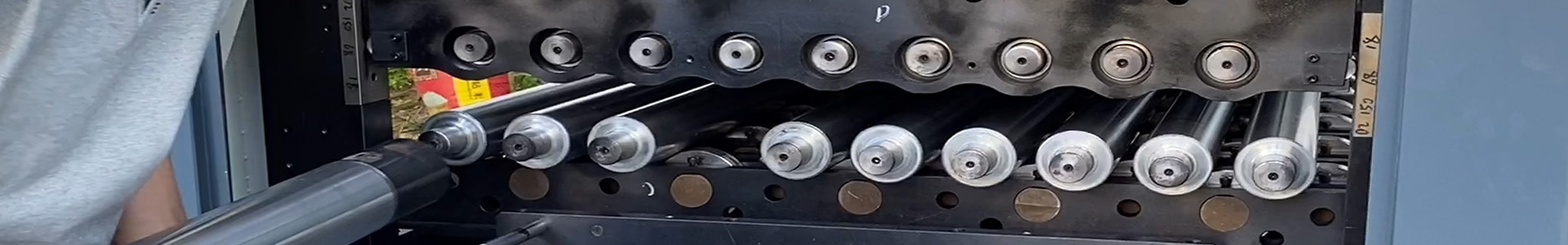

The working principle of a thick plate flattening machine is to apply pressure to the metal plate to flatten it. This machine is usually composed of large hydraulic presses that can generate high levels of force. Place the workpiece on the leveling machine workbench and flatten it over a period of time.

Once the board is flattened, it can be punched. The punching process involves creating holes or shapes on metal plates using a punch and mold set. Punching can cause bending and deformation of the workpiece, and flat plates can also be used for other types of metal processing processes, such as welding or cutting.

Overall, the thick plate stamping and leveling machine is an essential tool for any metal processing workshop that needs to process thick plate metal. It helps to ensure that the board is properly prepared for further processing, thereby improving the quality of the finished product.