Some cold rolled sheets require leveling before and after processing to ensure uniform thickness and flatness. This is particularly important for applications where precise measurements and smooth surfaces are required, such as in the automotive and aerospace industries.

During the cold rolling process, the sheet can become uneven due to variations in temperature, pressure, and material properties. This can result in a wavy or uneven surface, which can cause problems during subsequent processing steps.

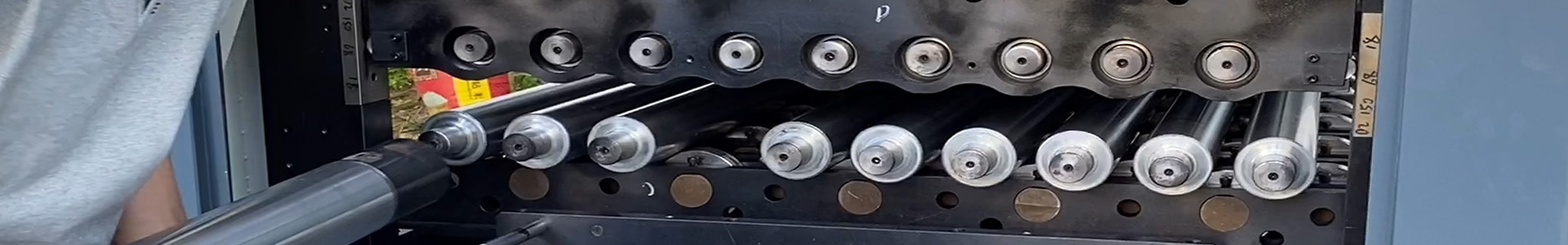

Leveling is a process that involves passing the sheet through a series of rollers that apply pressure to the surface, smoothing out any bumps or waves. This helps to ensure that the sheet is uniform in thickness and flatness, which can improve the quality and consistency of the final product.

After processing, the sheet may require leveling again to correct any distortions that may have occurred during cutting, bending, or other operations. This can help to prevent issues such as warping, twisting, or buckling, which can compromise the integrity of the part or component.

Overall, leveling is an important step in the production of cold rolled sheets, helping to ensure that they meet the stringent requirements of modern manufacturing industries.