Making flat aluminum stamping parts involves several steps:

1. Design: Start by designing the part using a CAD software. This will help you get the accurate dimensions and specifications of the part.

2. Material selection: Choose the right type of aluminum alloy for the part. This will depend on the application and the properties required.

3. Cutting: Cut the aluminum sheet to the required size using a cutting tool or machine.

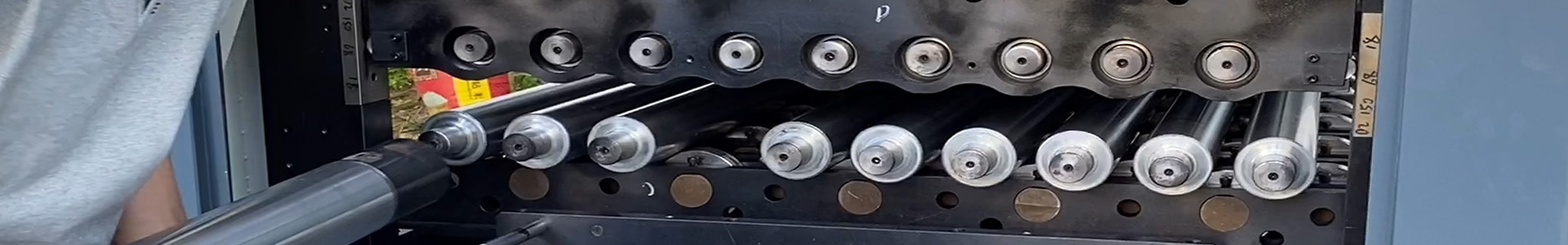

4. Blanking: This involves cutting the shape of the part out of the sheet of aluminum using a stamping die.

5. Forming: The blanked aluminum is then formed into the desired shape using a press machine.

6. Finishing: The part is then finished by removing any sharp edges or burrs.

7. Quality control: Inspect the finished part to ensure it meets the required specifications and dimensions.

8. Packaging: Finally, package the part carefully to prevent damage during transportation.

Overall, making flat aluminum stamping parts requires precision and attention to detail. It is essential to have the right equipment, expertise, and quality control measures in place to ensure the final product is of high quality and meets the required standards.