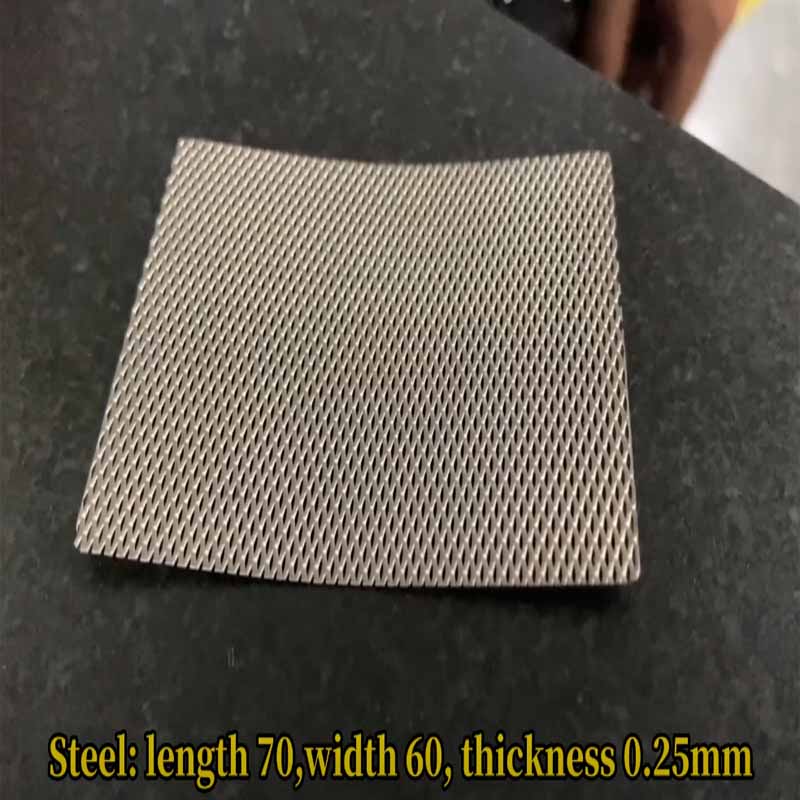

Perforated plates need to be leveled by a leveling machine to ensure that they are completely flat and free of any warping or distortion. When sheet metal is perforated, it can cause the material to bend, warp, or otherwise become distorted. This can cause issues with the final product, as it may not fit properly or may not function as intended.

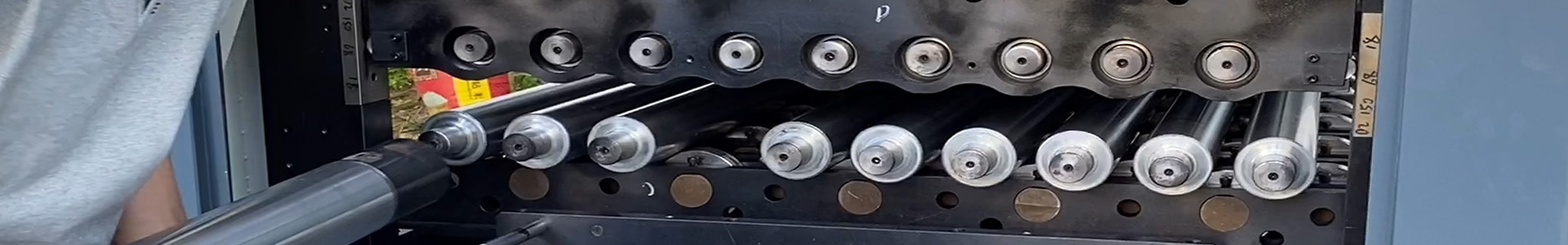

A leveling machine uses rollers and other processes to flatten and straighten the sheet metal, ensuring that it is completely flat and free of any warping or distortion. This is especially important for perforated plates, as any distortion can cause issues with the pattern of the perforations, as well as with the overall flatness of the plate.

By using a leveling machine to level perforated plates, manufacturers can ensure that their products are of the highest quality and that they will function properly when used in various applications. This is especially important for industries that require precision and accuracy, such as aerospace, automotive, and manufacturing.