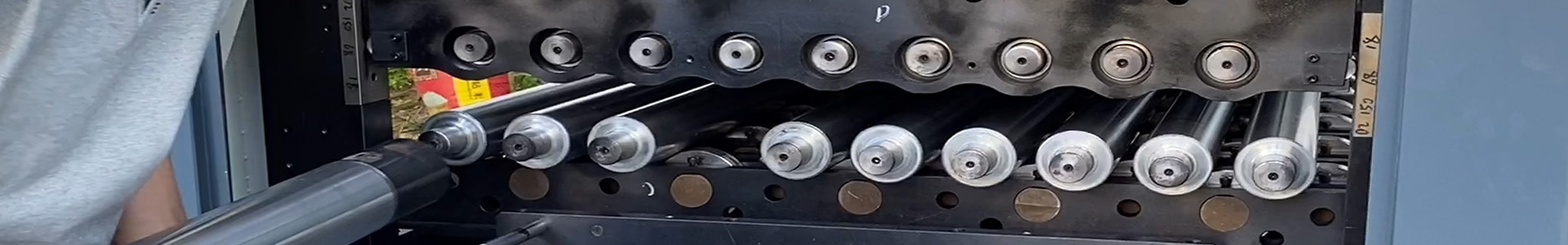

Metal cutting parts with high requirements for plane accuracy require leveling with a leveling machine after cutting

Some metal cutting parts require leveling treatment after cutting, especially for workpieces with high flatness requirements. Whether leveling treatment is required depends on the specific requirements of the part and the cutting process used.

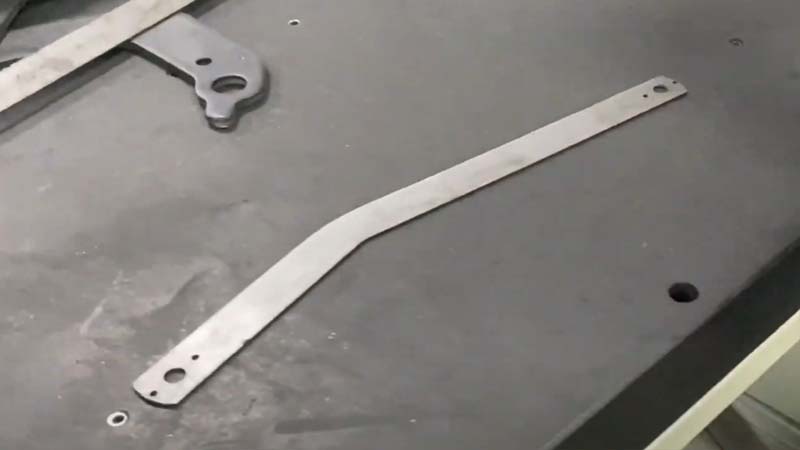

For example, some cutting processes, such as plasma cutting or water jet cutting, typically do not cause material warping or bending, and therefore may not require leveling. However, other cutting processes, such as laser cutting or flame cutting, may cause warping or bending due to the heat generated during the process. In these cases, it may be necessary to use a leveling machine to ensure that the material is flat and consistent after cutting.

In addition, some metal cutting parts may be designed with tolerances that allow for slight material changes, so these parts may not require leveling. This actually depends on the specific requirements of the part and the cutting process used.