Product Description

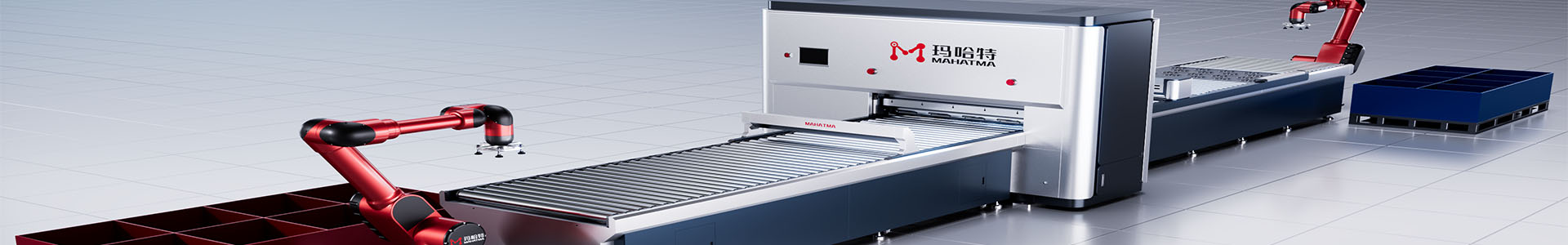

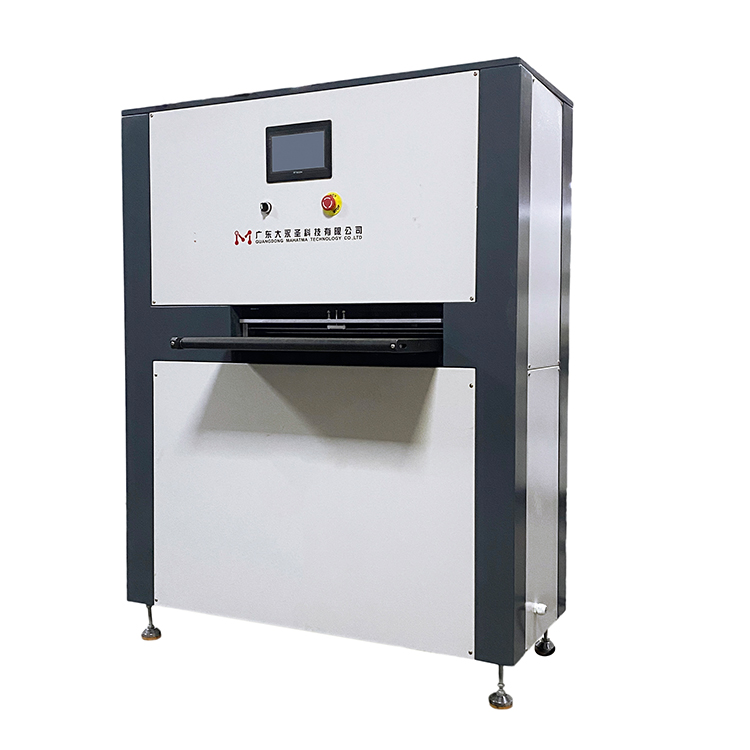

Under the condition of large elastic-plstic bending, no mater how different the original bending degree, precision levelling machine uses the "Bauschinger effect" of the material to bend the plate repeatedly, gradually reduce the bending deflection, and gradually change the origina curvature into a single curvature, and finally level it to achieve the leveling accuracy required by the process.

After a series of alternating bending, the sheet metal is controlled by the motor and the PLC to accurately control the lower pressure of each leveling drum,elminating the internal stress,and fundamentally solving the unsatisfactory leveling effect caused by the different stress in each part of the sheet metal,thus achieving high precision leveling.

Product Parameters

MHT200 Series sheet metal CNC precision leveler parameter table |

Machine Model | MHT200-450-15 | MHT200-600-15 | MHT200-800-15 | MHT200-1000-15 | MHT200-1300-15 | MHT200-1600-15 | MHT200-2100-15 |

Roller Diameter | φ200mm | φ200mm | φ200mm | φ200mm | φ200mm | φ200mm | φ200mm |

Roller Number | 15/19 | 15/19 | 15/19 | 15/19 | 15/19 | 15/19 | 15/19 |

Speed | 0-10m/Min | 0-10m/Min | 0-10m/Min | 0-10m/Min | 0-10m/Min | 0-10m/Min | 0-10m/Min |

Leveled Width | 0-450mm | 0-600mm | 0-800mm | 0-1000mm | 0-1300mm | 0-1600mm | 0-2100mm |

Rated Plate Thickness | 20~30mm | 20~30mm | 20~30mm | 20~30mm | 20~30mm | 20~30mm | 20~30mm |

Maximum Thickness | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

Shortest Workpiece | 310mm | 310mm | 310mm | 310mm | 310mm | 310mm | 310mm |

Applicable Object | Coil, plane parts, sheet materials, etc |

Detailed Photos

Roller straightener machines are essential equipment in the manufacturing industry. They are designed to straighten and flatten metal sheets, wires, and other small parts. These machines are commonly used in the production of galvanized small parts, which require a high level of precision and accuracy.

Galvanized small parts are widely used in a range of industries, including automotive, construction, and electrical. These parts are typically made of steel or other metal alloys and are coated with a layer of zinc to protect them from corrosion. Galvanization involves the process of applying a thin layer of zinc to the surface of a metal to form a protective barrier against rust and other forms of corrosion.

Roller straighteners for galvanized small parts are designed to straighten and flatten the metal sheets and wires used in the production of these parts. The machines use a series of rollers to apply pressure to the metal, which helps to remove any kinks or bends in the material. The rollers are positioned at precise intervals along the length of the machine, which ensures that the metal is straightened evenly and accurately.

One of the key benefits of using a roller straightener for galvanized small parts is that it can improve the quality of the finished product. Galvanized small parts that have been straightened using a roller straightener are much more likely to meet the required specifications for size and shape. This can help to reduce the number of defective parts produced, which can save manufacturers time and money.

Another advantage of using a roller straightener for galvanized small parts is that it can improve the efficiency of the production process. The machines are capable of straightening large volumes of metal sheets and wires in a relatively short amount of time. This can help to increase the output of the manufacturing process, which can lead to higher profits for the manufacturer.

Roller straighteners for galvanized small parts are also very versatile machines. They can be used to straighten a wide range of different metal alloys, including steel, aluminum, and copper. This makes them a valuable asset for manufacturers who work with a variety of different metals.

In addition to their versatility, roller straighteners for galvanized small parts are also very easy to operate. They require minimal training to use, and most models come with user-friendly controls that allow operators to adjust the tension and speed of the rollers. This makes it easy for manufacturers to incorporate these machines into their existing production processes.

Roller straighteners for galvanized small parts are an essential piece of equipment for manufacturers who produce metal parts. They can improve the quality and efficiency of the production process, and they are capable of straightening a wide range of different metal alloys. Whether you are a small business or a large manufacturer, investing in a roller straightener for galvanized small parts can help you to produce high-quality parts that meet the required specifications.