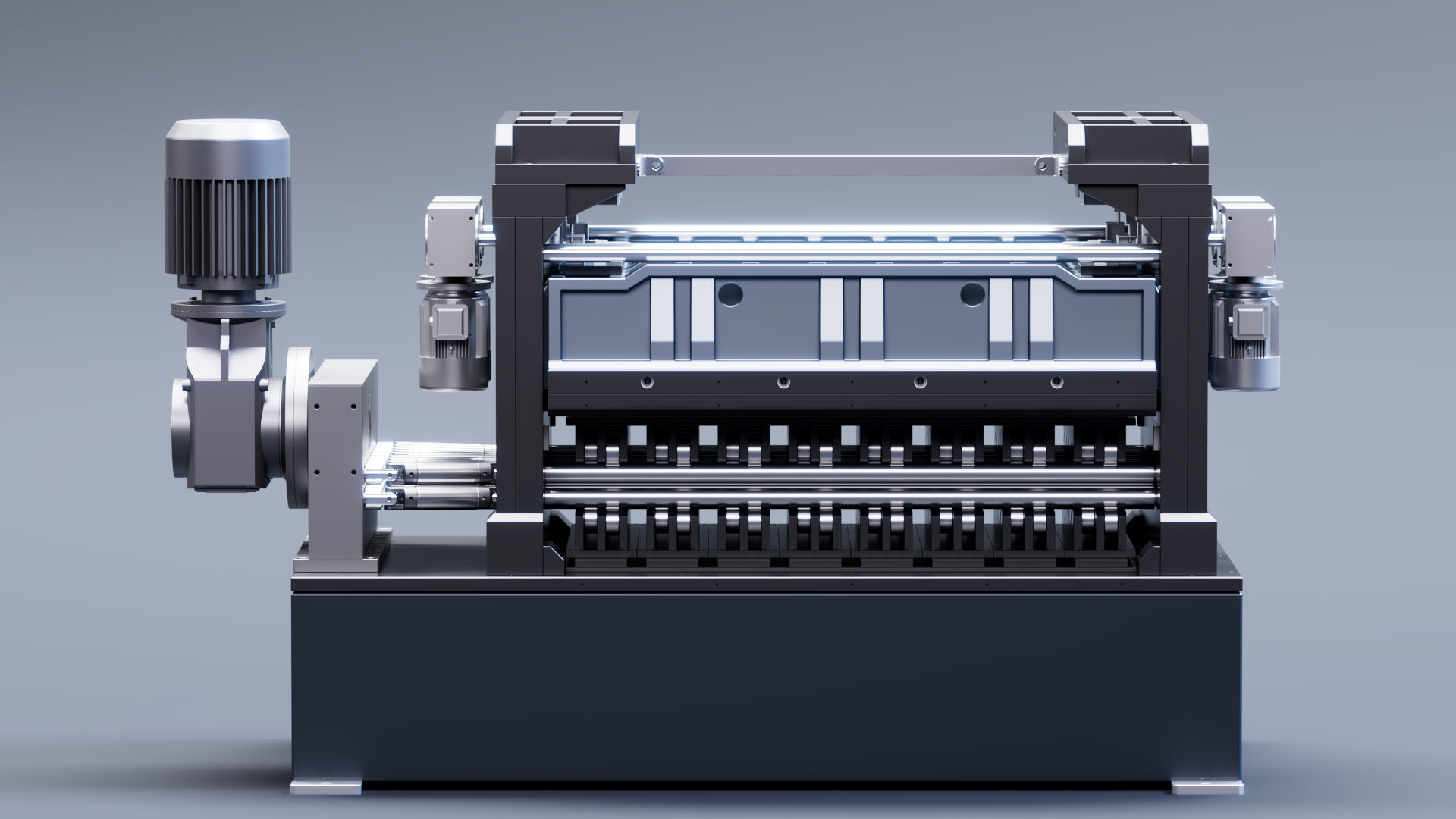

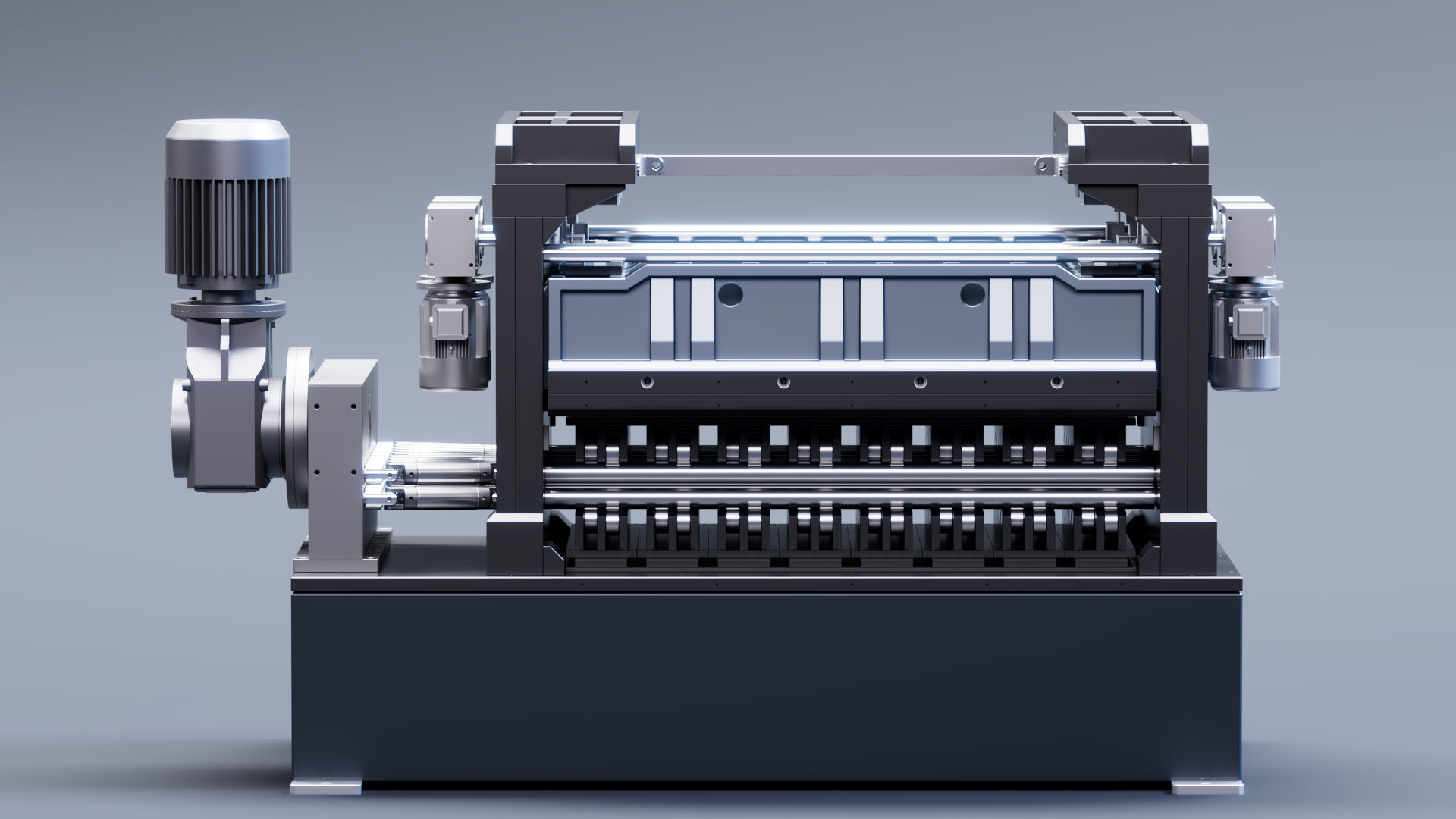

Under large elastic-plastic bending conditions, regardless of the difference in the original bending degree of metal materials, CNC Metal Straightening Machine use the "Bauschinger effect" of the material to repeatedly bend the plate multiple times, gradually reducing the bending deflection, gradually changing multiple original curvatures into a single curvature, and leveling them to achieve the required flatness accuracy of the process. CNC Metal Straightening Machines have been widely used in industry, with advanced technology, high leveling accuracy, wide process range, high degree of automation, and reliable and stable operation under high strength. During the roller leveling process, the metal sheet undergoes a series of alternating bending, and the precise control of the downward pressure of each leveling drum is achieved through motor and PLC control, eliminating internal stress, Fundamentally solving the problem of unsatisfactory leveling effect caused by different stresses in various parts of the board, thus achieving high-precision leveling.

Compared with other leveling methods, the control system of this machine has functions of storing, calling, editing process and equipment parameters, as well as misoperation identification and warning. When in use, on the operating platform, the inlet and outlet pressure reduction can be set based on parameters such as plate thickness, plate width, material strength, or existing parameters in the database, to achieve electric adjustment of work roll clearance, and can be manually adjusted and corrected.

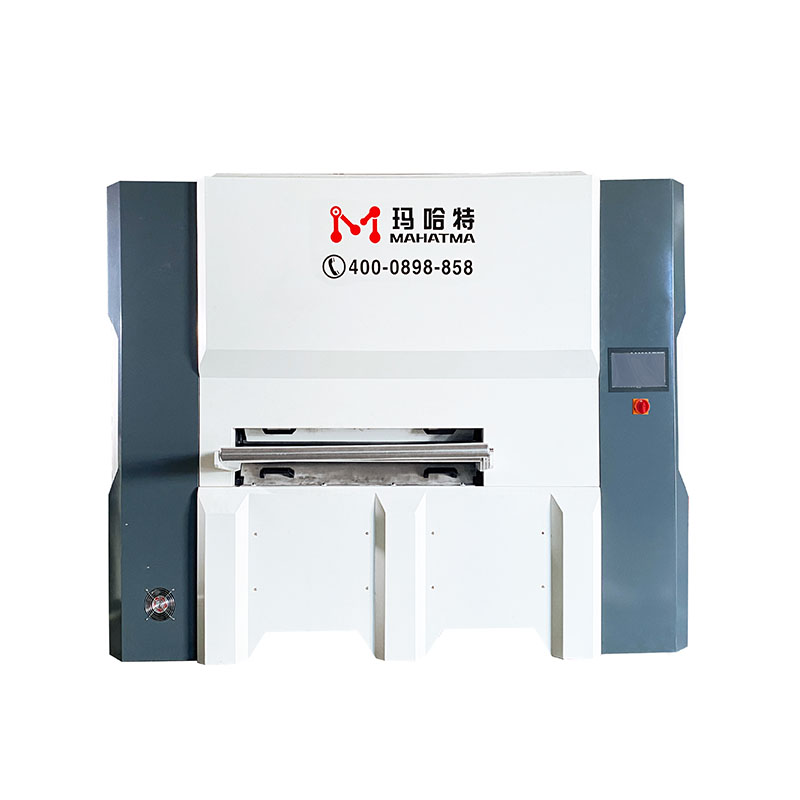

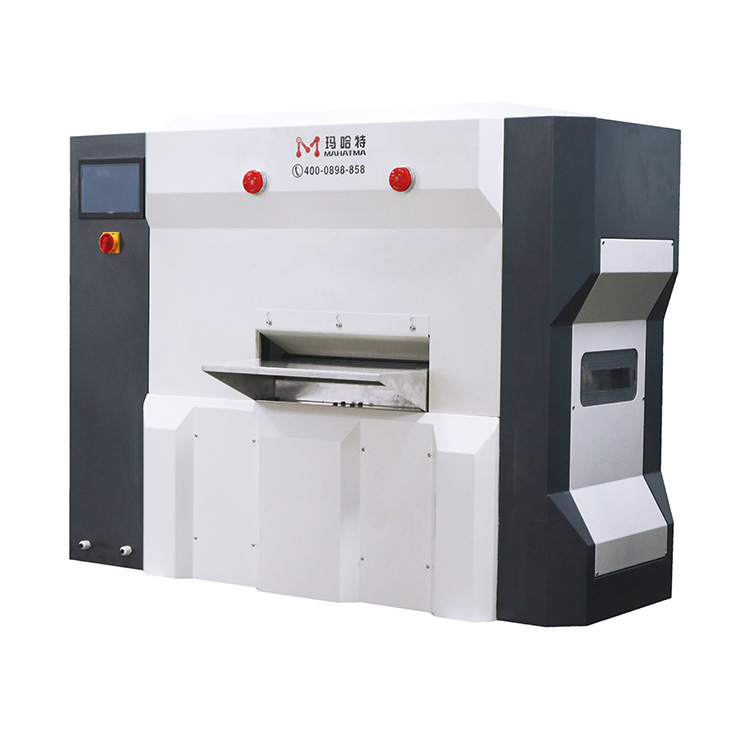

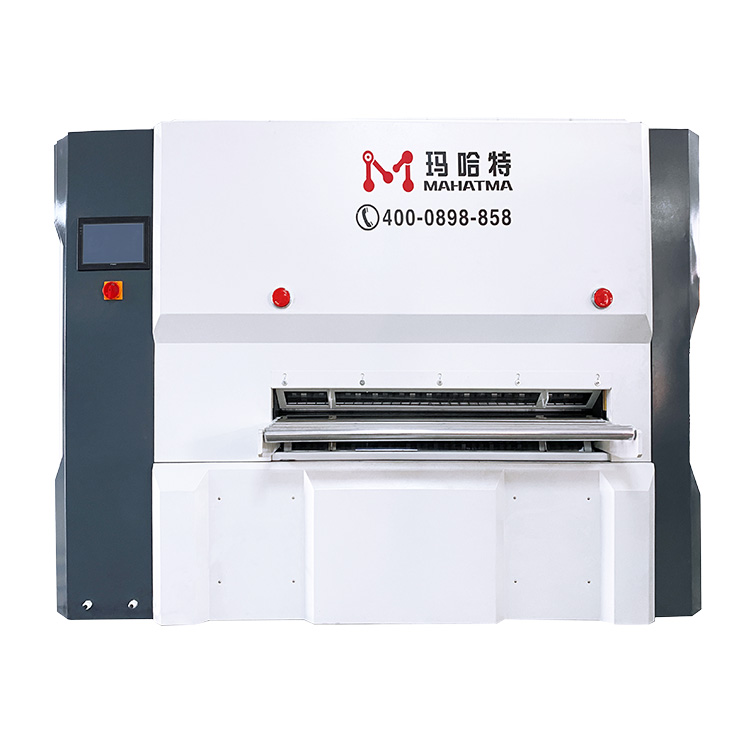

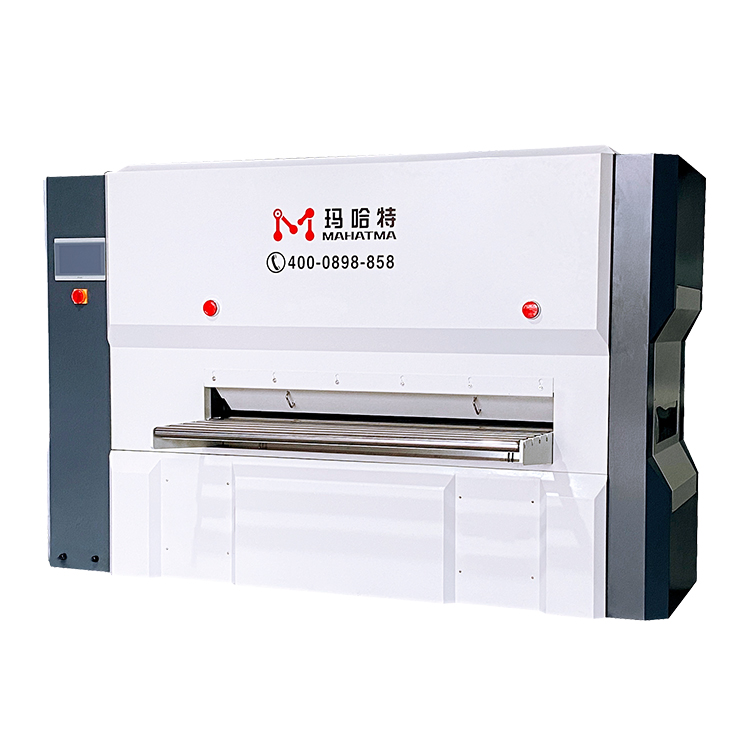

Features of Metal Straightening Machine

1. The auxiliary wheel reduces the gap between the upper and lower straightening rollers, ensuring higher leveling accuracy;

2. 10 inch high-precision touch screen display, PLC control, visual input, editing, modification, and storage of process parameters; Adjust the descent point up and down;

3. Stamped parts, plates, and parts can be made flat and almost stress free in just a few minutes;

4. Precision leveling machine is a metal plate that has been repeatedly bent through a large number of staggered leveling rollers, and the bending amount can be adjusted to achieve the required bending plan for leveling lock, so it does not damage the appearance of the plate;

5. After repeated bending of the sheet metal, the length of the metal fibers gradually becomes consistent, and the internal stress of the material is eliminated at the same time. The metal sheet is naturally flattened;

6. Many users use cutting methods to achieve flatness, and using precision leveling machines can save a lot of materials;

7. Due to the use of continuous and repeated bending technology, the precision leveling machine has greatly improved the leveling efficiency and entered the continuous production line, saving a lot of labor costs and breaking away from the technical dependence of traditional leveling experience;

8. The use of universal joint transmission joint has greater strength, uniform transmission force, low noise and more durable equipment!

| Servo Hydraulic Leveling Machine Parameters |

| Model | MHTM40 | MHTM50 | MHTM60 | MHTM80 |

| Leveled Width | 0-1600mm | 0-1700mm | 0-1650mm | 0-1650mm |

| Roller Diameter | φ40mm | φ50mm | φ60mm | φ80mm |

| Roller Number | 21 | 19 | 19 | 19 |

| Rated Thickness(Q235) | 0.6~3.0mm | 0.8~4.0mm | 1.0~6.0mm | 2.0~8.0mm |

| Maximum Thickness(Q235) | 6.0mm | 8.0mm | 12.0mm | 16.0mm |

| Shortest Workpiece | 70mm | 90mm | 100mm | 130mm |

| Leveling Speed | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min |

| Voltage | AC three-phase 380VAC | AC three-phase 380VAC | AC three-phase 380VAC | AC three-phase 380VAC |