A saw blade leveling machine is a piece of equipment designed to accurately level and balance saw blades used in various cutting applications. The machine is essential for maintaining the precision and accuracy of cutting equipment, which is critical for ensuring the quality of the final product.

Saw blade leveling machines are used in a variety of industries, including woodworking, metalworking, and construction. They are most commonly used to level circular saw blades, but can also be used for other types of saw blades, such as band saw blades.

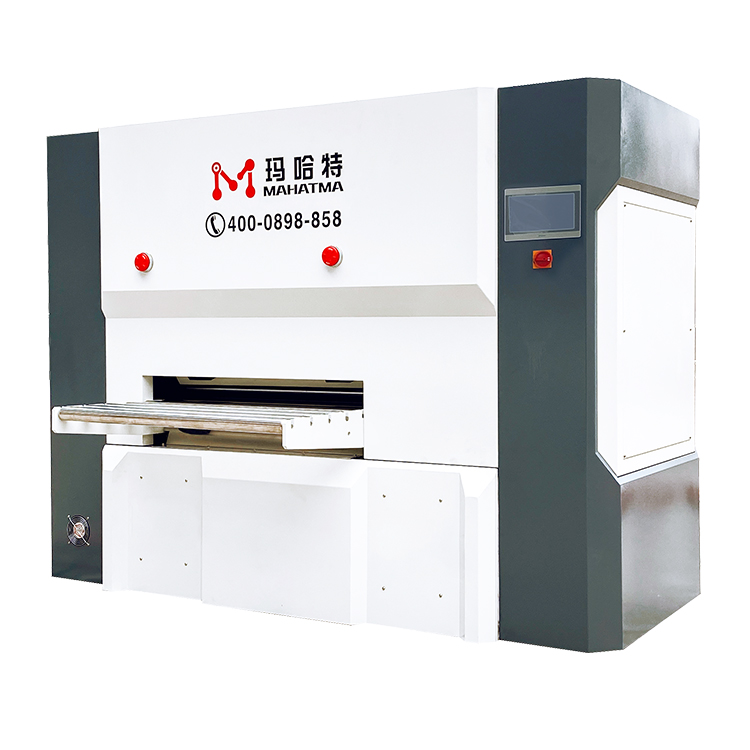

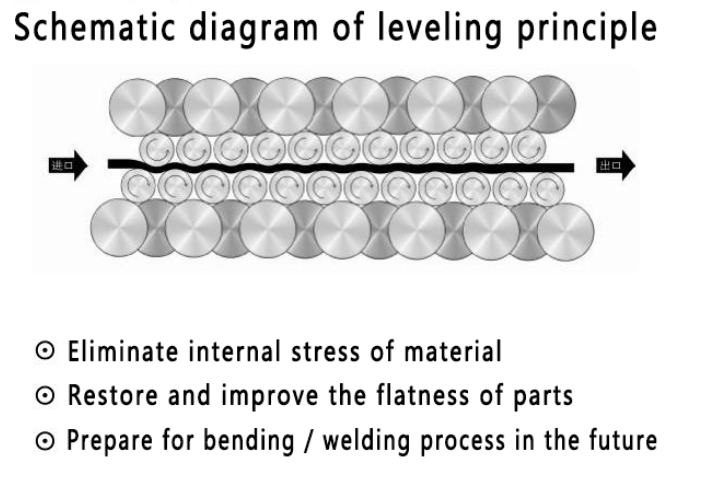

The machine works by mounting the saw blade on a spindle, which is driven by an electric motor. The blade is then rotated at a high speed while a laser sensor measures the blade's position and levelness. The machine's software then calculates the amount of material that needs to be removed from the blade to achieve a perfectly level surface.

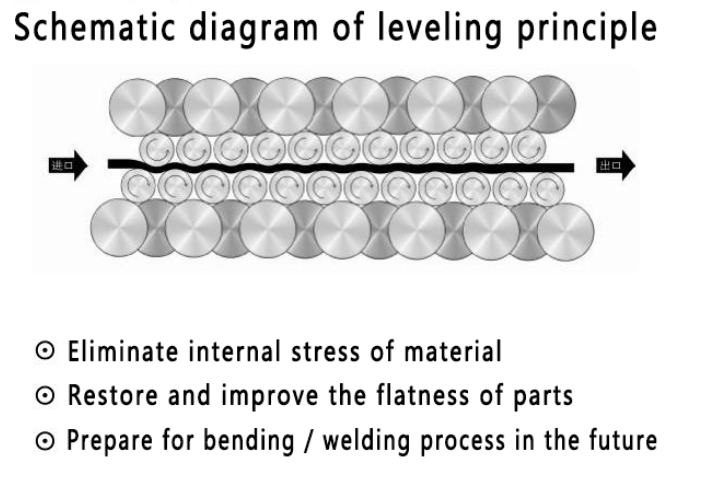

The leveling process involves removing a small amount of material from the saw blade's teeth and body. This is done using a precision grinding wheel that is mounted on a separate spindle. The grinding wheel is moved across the surface of the blade, removing material as it goes.

Once the blade has been leveled, it is then balanced. This is done by measuring the weight distribution of the blade and adding or removing material as necessary to achieve an even balance. Unbalanced blades can cause vibration, which can lead to inaccurate cuts and even damage to the cutting equipment.

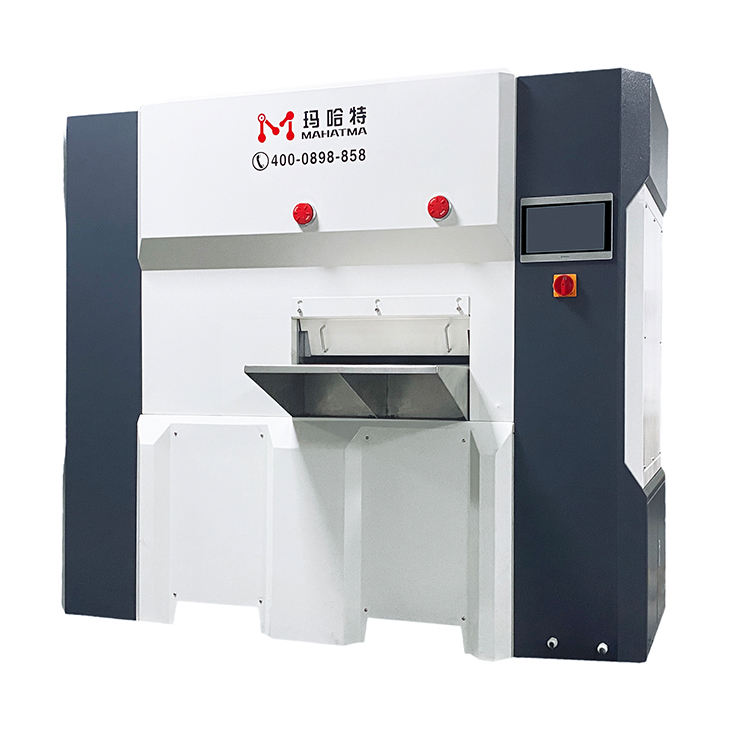

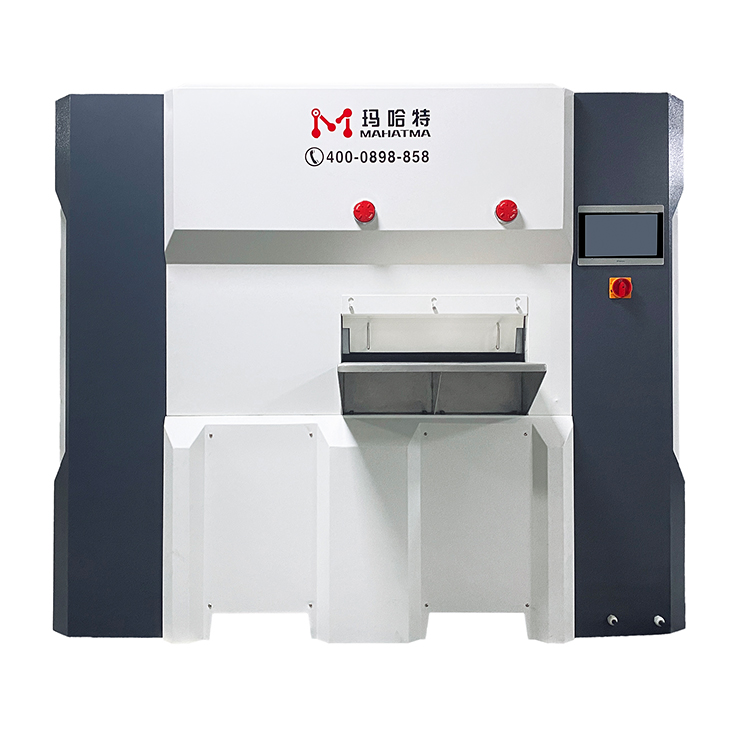

Saw blade leveling machines come in a variety of sizes and configurations, depending on the size and type of saw blades they are designed to work with. Some machines are designed to level and balance only one type of saw blade, while others can handle a variety of sizes and types.

One of the key benefits of using a saw blade leveling machine is the increased accuracy and precision it provides. By ensuring that the saw blade is perfectly level and balanced, the machine helps to minimize the risk of errors and defects in the final product. This is particularly important in applications where accuracy and precision are critical, such as in the production of high-end furniture or precision metal parts.

Another benefit of using a saw blade leveling machine is the increased lifespan of the cutting equipment. By ensuring that the saw blade is level and balanced, the machine helps to reduce the amount of wear and tear on the blade, which can extend its lifespan and reduce the need for costly replacements.

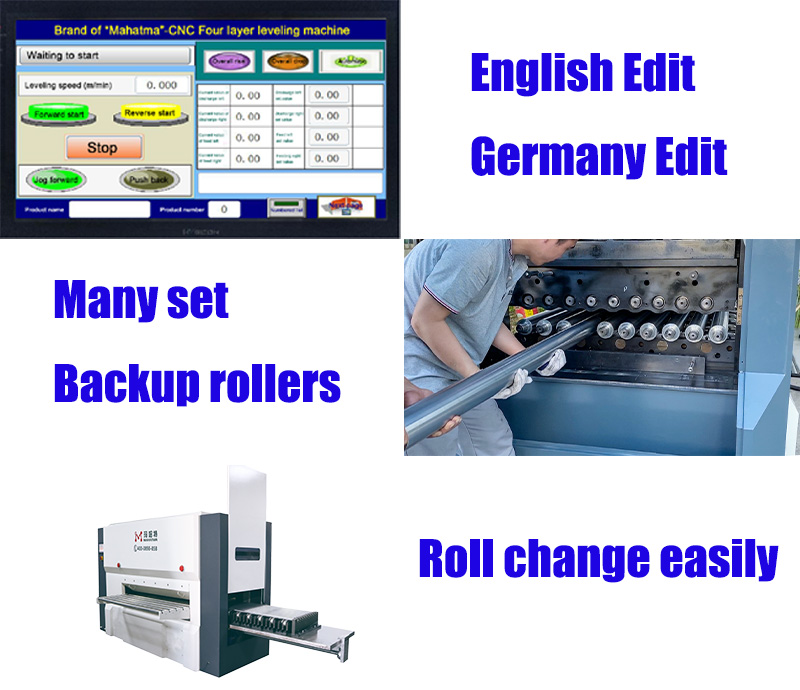

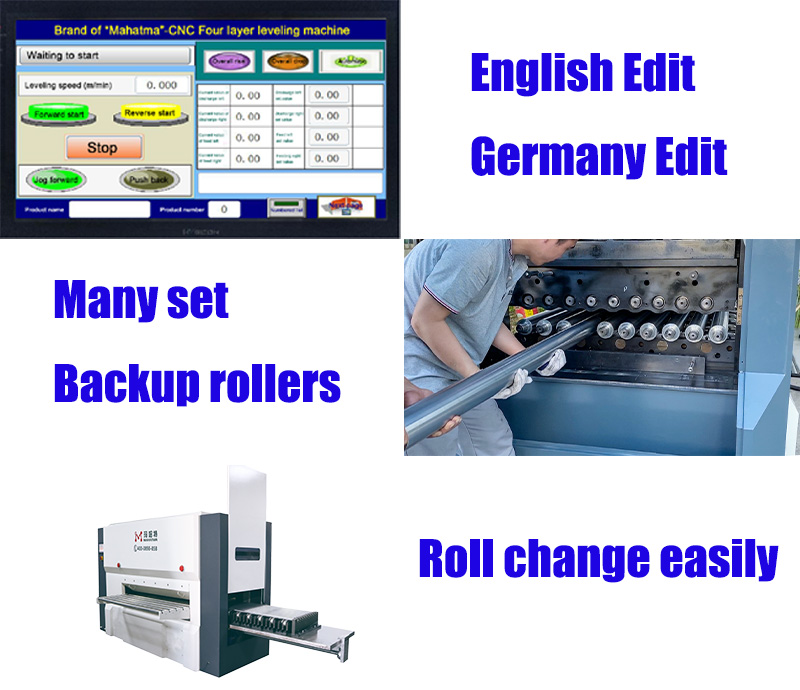

Saw blade leveling machines are also relatively easy to use, with most models featuring intuitive controls and user-friendly software. This means that even operators with minimal training can quickly and easily level and balance saw blades, saving time and reducing the risk of errors.

In addition to their benefits for accuracy, precision, and equipment lifespan, saw blade leveling machines can also help to improve workplace safety. By ensuring that the cutting equipment is functioning properly and free from defects, the machine helps to reduce the risk of accidents and injuries in the workplace.

Overall, saw blade leveling machines are an essential piece of equipment for anyone involved in cutting applications. Whether working with wood, metal, or other materials, these machines can help to ensure the quality, accuracy, and safety of cutting equipment, ultimately leading to better products and a more efficient workplace.