Sheet metal levelers are essential tools in the metalworking industry, particularly in the fabrication and manufacturing of various products. These machines play a crucial role in ensuring that sheet metal is perfectly flat and smooth before it undergoes the punching process. By providing a uniform and level surface, sheet metal levelers greatly enhance the accuracy and quality of punched parts. In this article, we will explore the significance of sheet metal levelers for punching parts, their features, and the benefits they offer.

Sheet metal levelers are specifically designed to flatten and straighten sheet metal, which is essential for achieving precise and accurate punched parts. When sheet metal is not level, it can result in distorted or uneven punched holes, leading to compromised product quality. This is particularly critical in industries such as automotive, aerospace, and electronics, where precision and consistency are of utmost importance.

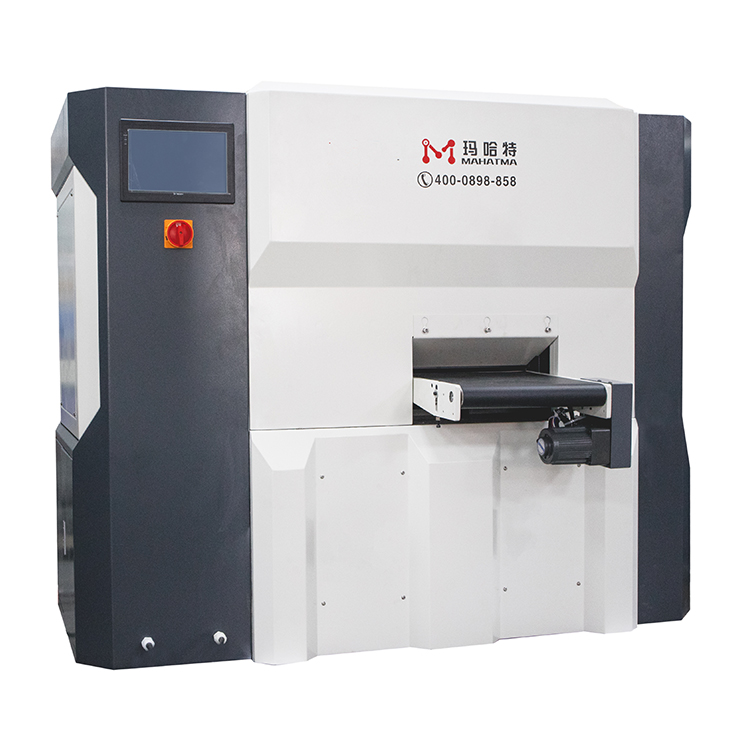

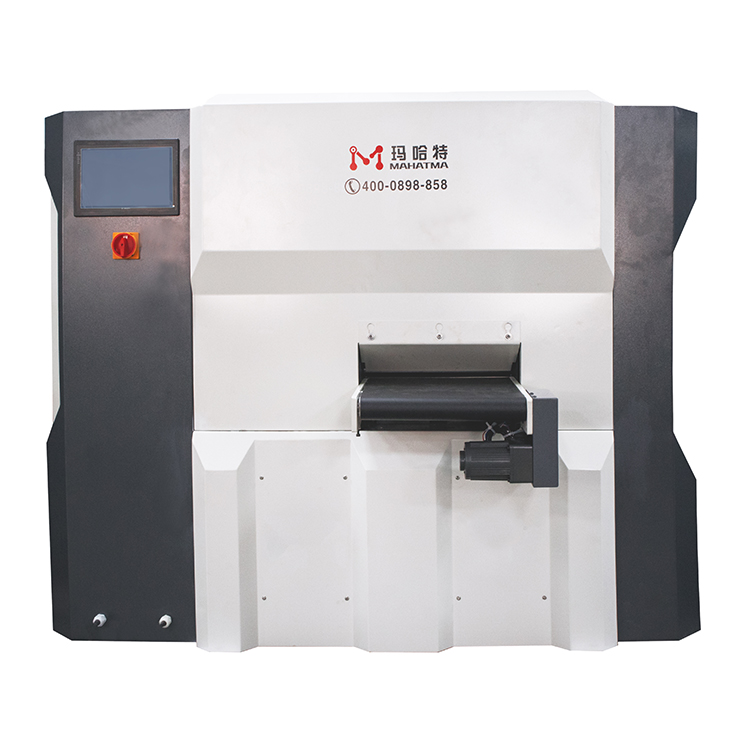

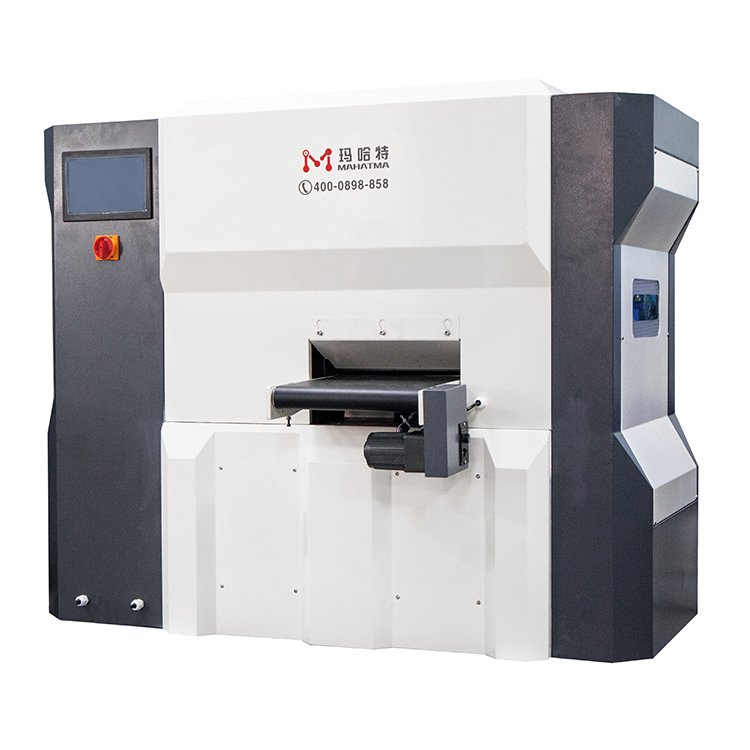

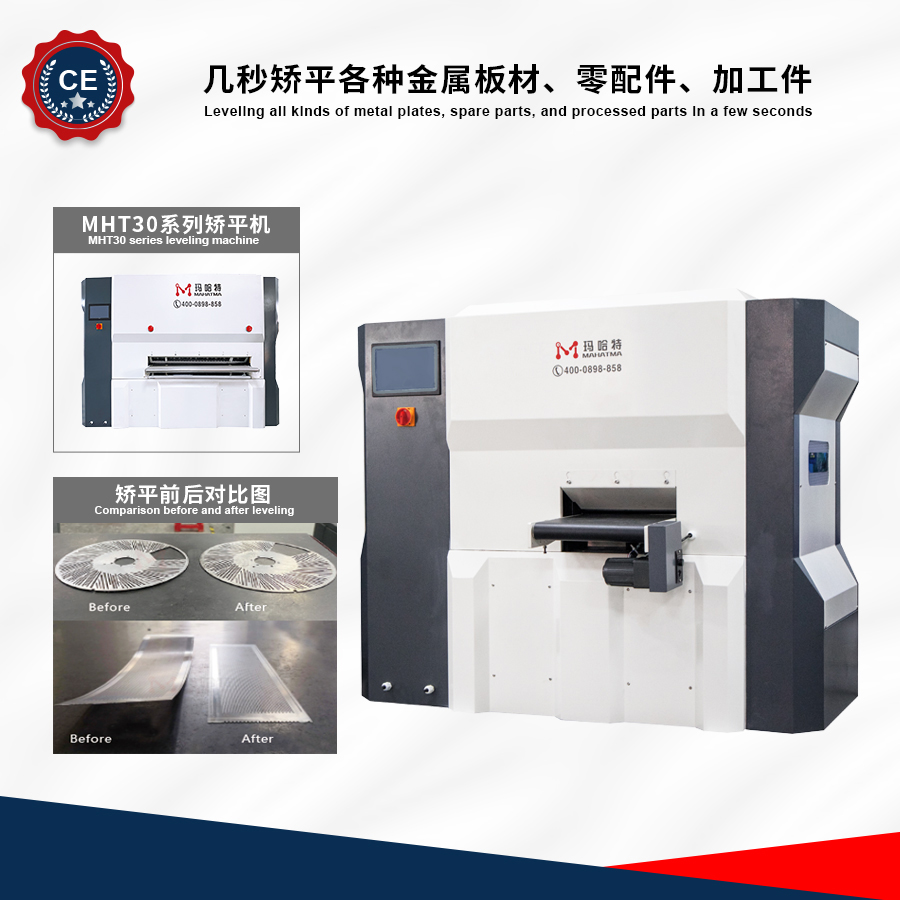

One of the key features of a sheet metal leveler for punching parts is its ability to handle various thicknesses of sheet metal. These machines are equipped with adjustable settings that allow operators to set the desired level of flattening based on the specific requirements of the punched parts. This flexibility ensures that the leveler can be used for a wide range of applications, accommodating different sheet metal thicknesses and materials.

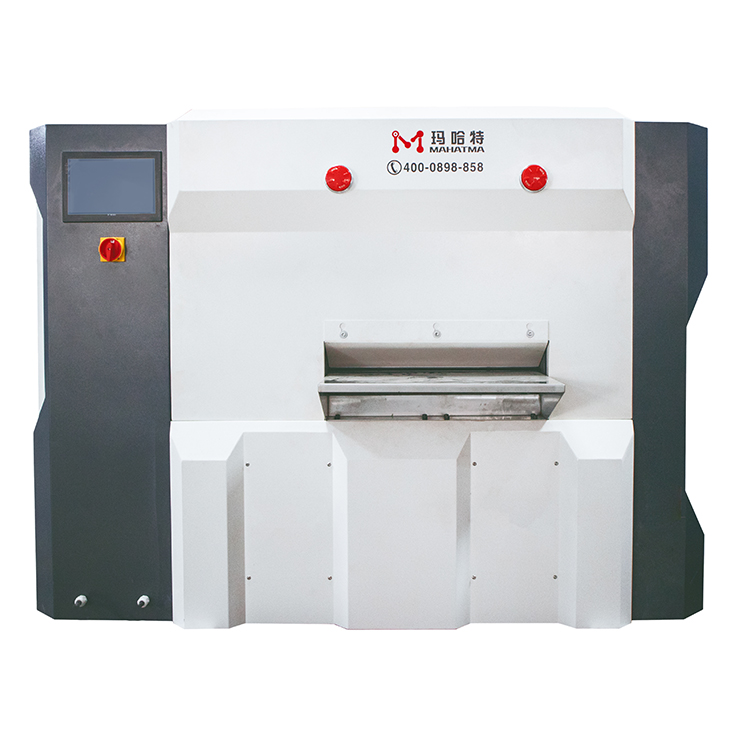

Sheet metal levelers for punching parts also come with advanced control systems that enable operators to monitor and adjust the leveling process. These control systems allow for precise adjustments, ensuring that the sheet metal is flattened uniformly across its entire surface. This not only improves the quality of punched parts but also reduces material waste by avoiding over-leveling.

Additionally, sheet metal levelers are equipped with robust and durable construction to withstand the rigorous demands of the metalworking industry. They are typically made of high-quality materials such as hardened steel, which ensures their longevity and resistance to wear and tear. This durability is essential, as sheet metal levelers are often subjected to heavy usage in high-volume production environments.

Another important feature of sheet metal levelers is their ease of use and user-friendly interfaces. These machines are designed to be intuitive and straightforward, allowing operators to quickly set up and operate them with minimal training. This ensures efficiency in the production process, as operators can easily adjust and optimize the leveling parameters to meet specific requirements.

The benefits of using sheet metal levelers for punching parts are numerous. First and foremost, they significantly improve the accuracy and precision of punched parts. By providing a perfectly level surface, these machines eliminate any distortion or irregularities in the sheet metal, resulting in clean and consistent punched holes. This, in turn, enhances the overall quality of the final product.

Moreover, sheet metal levelers help to minimize material waste by avoiding over-leveling. By precisely controlling the flattening process, these machines ensure that only the necessary amount of material is removed, optimizing resource utilization. This not only reduces costs but also contributes to a more sustainable and environmentally friendly manufacturing process.

Furthermore, sheet metal levelers enhance the productivity and efficiency of the punching process. By eliminating the need for manual leveling, these machines streamline the production workflow, reducing the time and effort required to prepare sheet metal for punching. This allows manufacturers to meet tight production deadlines and increase their output without compromising quality.

In conclusion, sheet metal levelers are indispensable tools for punching parts in the metalworking industry. They play a crucial role in ensuring that sheet metal is perfectly flat and smooth before it undergoes the punching process, leading to precise and accurate punched parts. With their adjustable settings, advanced control systems, and user-friendly interfaces, these machines offer numerous benefits, including improved accuracy, reduced material waste, and increased productivity. Investing in a high-quality sheet metal leveler is essential for any manufacturer looking to produce high-quality punched parts efficiently and effectively.