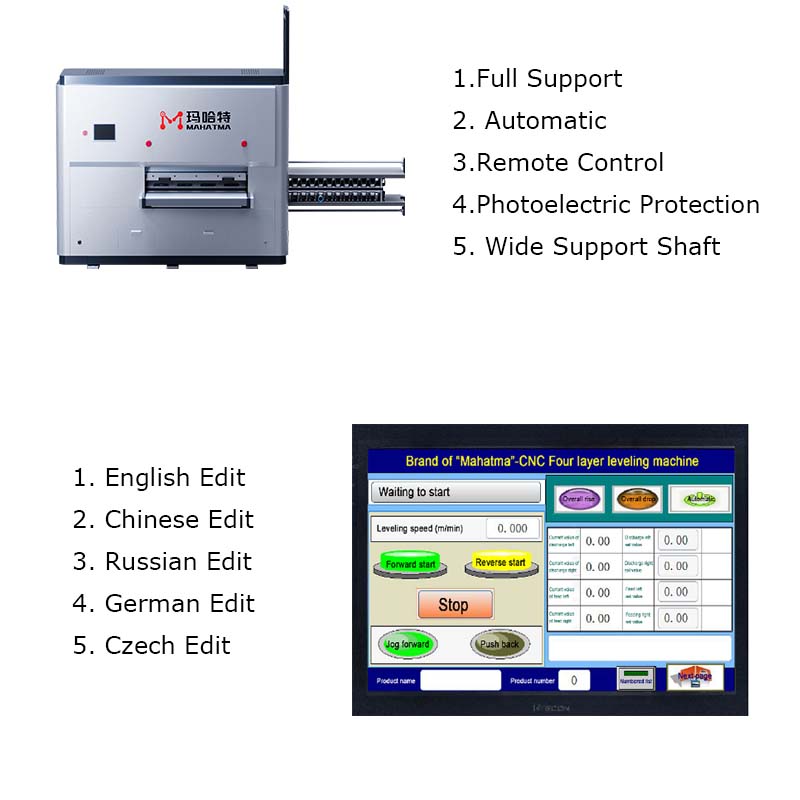

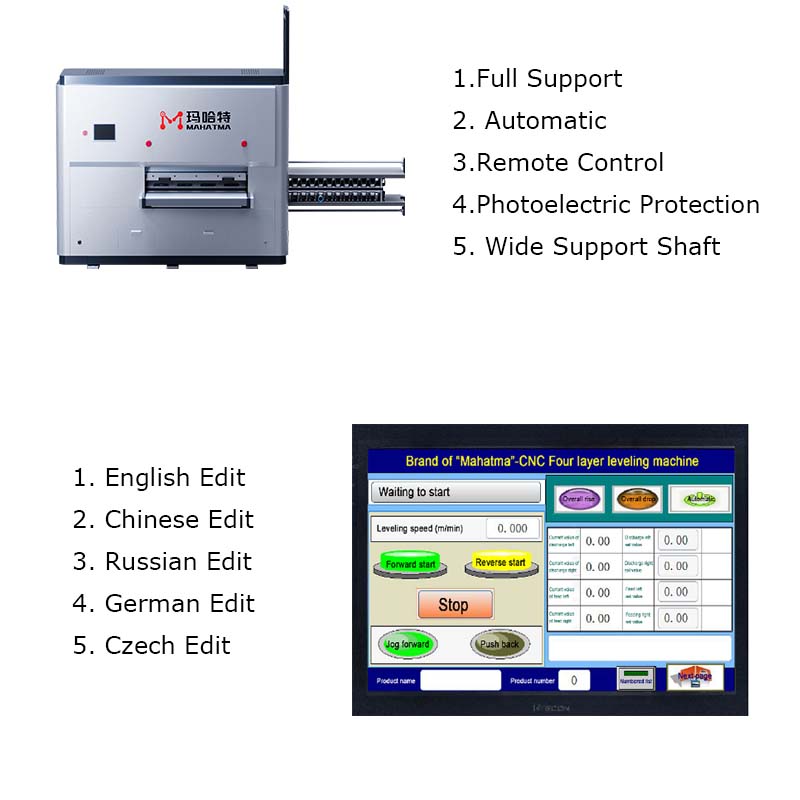

The machine has the function of storing, calling, editing process and equipment parameters and the function of misoperation identification and early warning. When in use, on the operating table, the touch screen in Chinese and English can set the input and outlet pressure according to the plate thickness, plate width and other parameters or the existing parameters in the database, so as to realize the electric adjustment of the work roll out and entry gap, and manual adjustment and correction. In order to solve the customer needs, we also added the remote service function of the system.

Product Features

★ The roller can be fully automatically extracted (convenient for cleaning the roller)

★ Automatic quantity calculation (can be connected to various MRP and ERP systems for control, automatic setting and monitoring of equipment startup time, effective working time, and automatic counting of processed parts)

★ Full support (the entire roller is fully supported, with strong structural force)

★ Automatic monitoring function (convenient for monitoring equipment and production status at any time, convenient for repair and maintenance)

★ Wide support shaft (improves the operating rigidity of the leveling roller and reduces indentation on a larger range)

★ Remote control function (for customers in remote areas, our engineers can help customers solve problems such as not being able to adjust machines or equipment malfunctions at any time)

★ Optoelectronic protection (to avoid unnecessary safety hazards caused by personnel or workpieces entering the equipment by mistake)

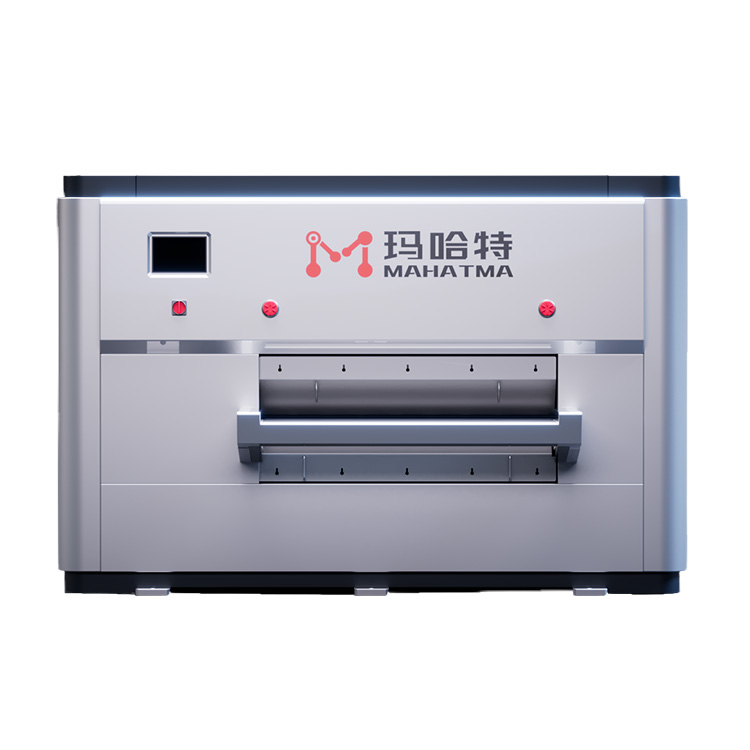

★ BMW paint (using high-end BMW baking paint, the whole machine is stable, high-end, and luxurious)

★ Automatic flatness detection (automatic scanning accuracy detection) (optional)

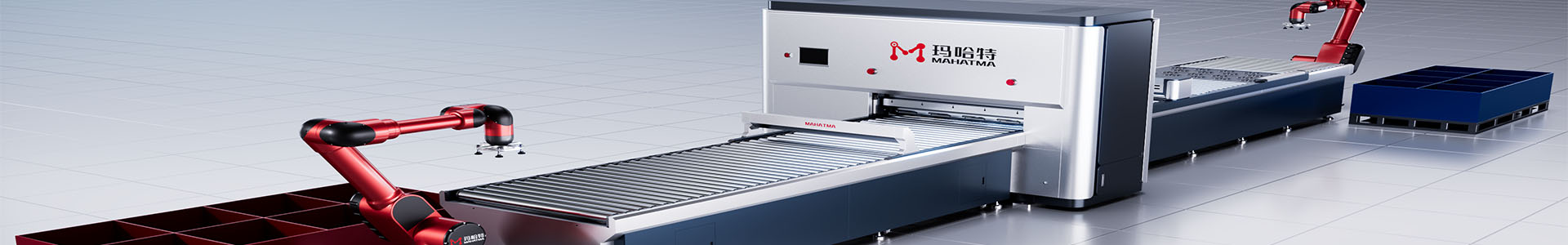

★ Unmanned and fully automatic adjustment of the entire line (optional)

1. Intelligent operating system

New style, powerful dynamic performance and stability, improving software operation smoothness; Integrated fast intelligent leveling mode;

2. MHTP series high-precision leveling machine

Independent intellectual property rights, multiple patented technologies, ultra-high efficiency leveling, intelligent control;

3. All machine tool self-lubricating system

High intelligence, high integration, maintenance free, one click setting of low oil pressure alarm, no oil shutdown, to avoid machine wear caused by delayed lubrication;

4. Remote cloud control system

Can achieve remote monitoring of equipment operation status, fault inquiry, fault diagnosis, etc., and real-time cloud monitoring of equipment;

5. Independently developed gearbox

Gear universal joint transmission, faster acceleration and speed, better rigidity and impact resistance;

6. Hollow structure machine tool

The main body of the machine tool has no heating area and is permanently used without thermal deformation. The machine body is stable and reliable, ensuring long-term stability of leveling accuracy.

| Sheet Metal Leveling Machine Parameter Table |

| Machine Model | MHTP60 | MHTP80 |

| Roller Diameter | φ60mm | φ80mm |

| Roller Number | 21 | 19 |

| Speed | 0-10m/Min | 0-10m/Min |

| Leveled Width | <2100mm | <2100mm |

| Rated Plate Thickness | 1.0~6.0mm | 2.0~8.0mm |

| Maximum Thickness | 12 | 16mm |

| Shortest Workpiece | 100mm | 130mm |

| Applicable Object | Laser cutting part,Sheet Metal |