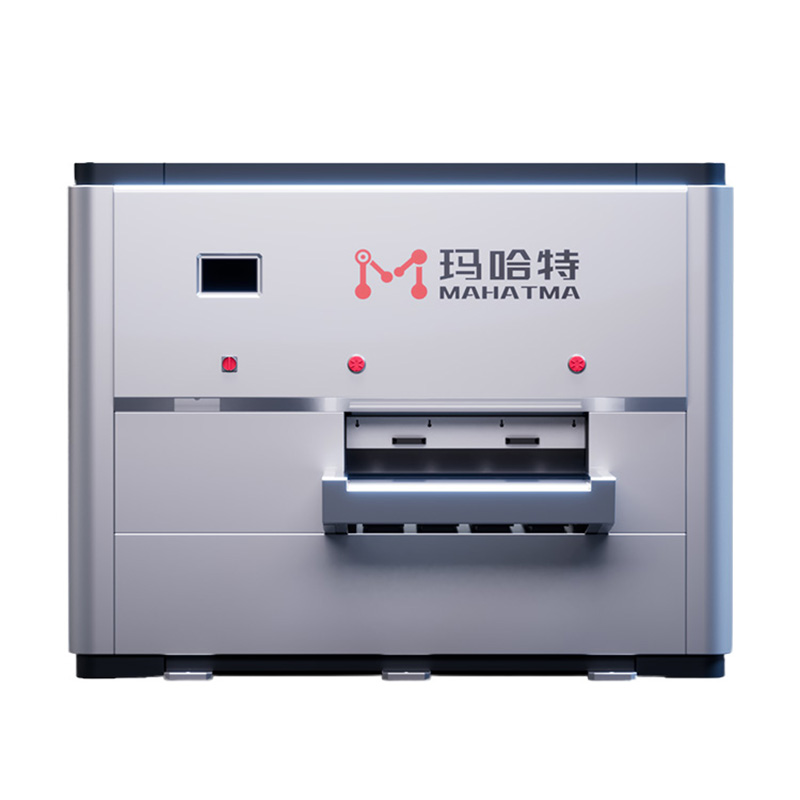

| Sheet Metal Leveling Machine Parameter Table |

| Machine Model | MHTP80 | MHTP100 | MHTP120 |

| Roller Diameter | φ80mm | φ100mm | φ120mm |

| Roller Number | 21 | 21 | 21 |

| Speed | 0-10m/Min | 0-10m/Min | 0-10m/Min |

| Leveled Width | <1600mm | <2500mm | <2500mm |

| Rated Plate Thickness | 2.0~8.0mm | 3.0~12.0mm | 4.0~16.0mm |

| Maximum Thickness | 4mm | 4mm | 4mm |

| Shortest Workpiece | 12mm | 15mm | 20mm |

| Applicable Object | Laser cutting part |

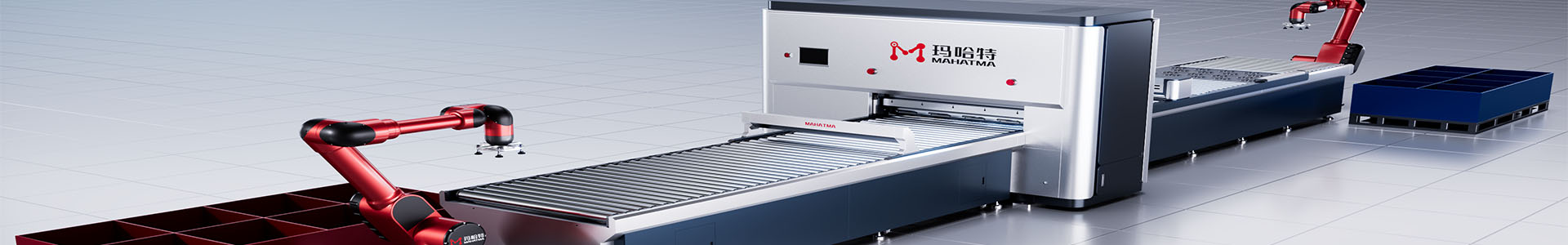

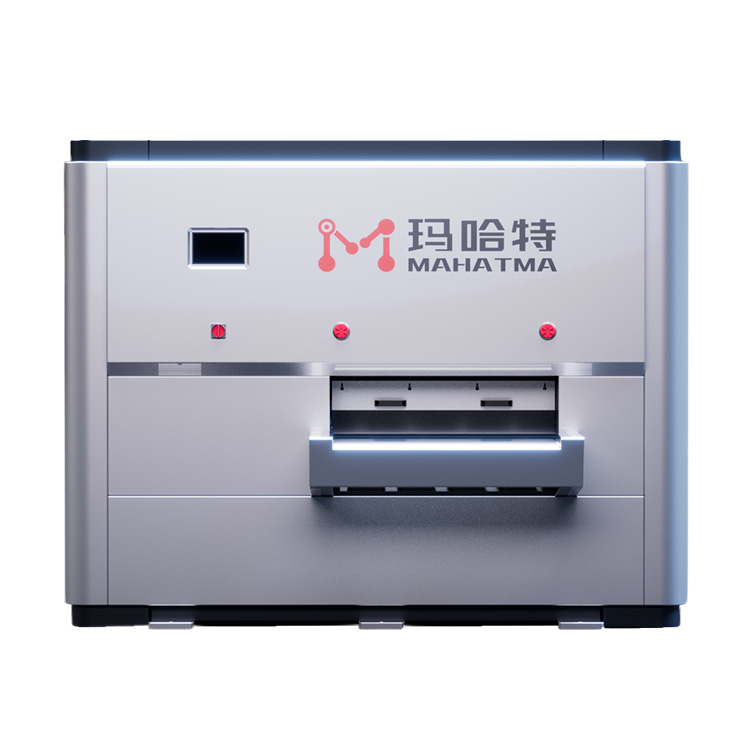

Sheet metal leveling machines are a vital tool in the metalworking industry, used to flatten and straighten sheets of metal and reduce waste. However, traditional leveling machines are not suitable for thick cutting parts. This is where the sheet metal leveling machine for thick cutting parts comes in.

The sheet metal leveling machine for thick cutting parts is a specialized tool that can handle thicker metal sheets than traditional leveling machines. These machines are designed for use in industries such as construction, shipbuilding, and heavy machinery manufacturing, where large, thick metal parts are frequently used.

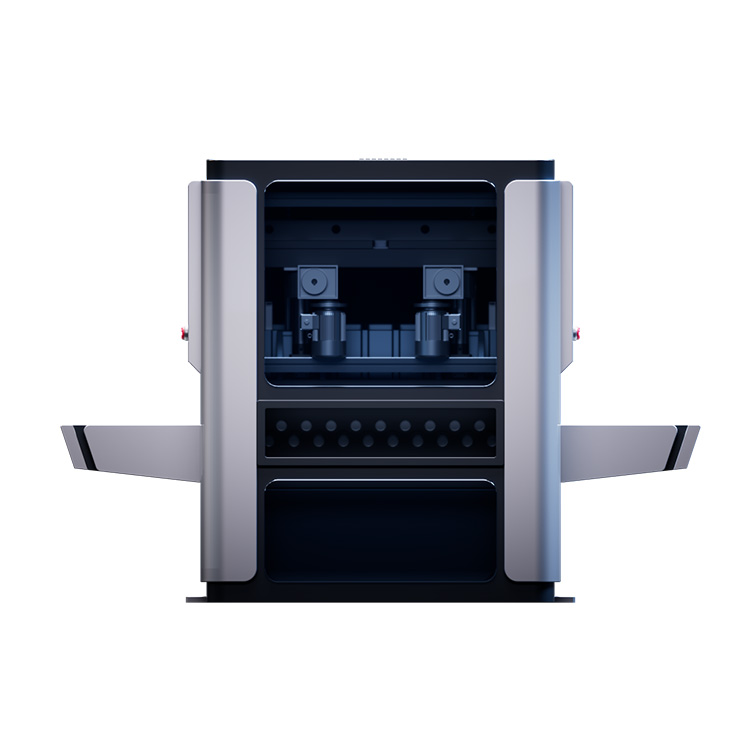

These machines work by feeding the sheet of metal through a series of rollers that apply pressure to the metal, flattening and leveling it out. The rollers are designed to be adjustable, allowing the operator to adjust the pressure and spacing between the rollers to achieve the desired level of flatness.

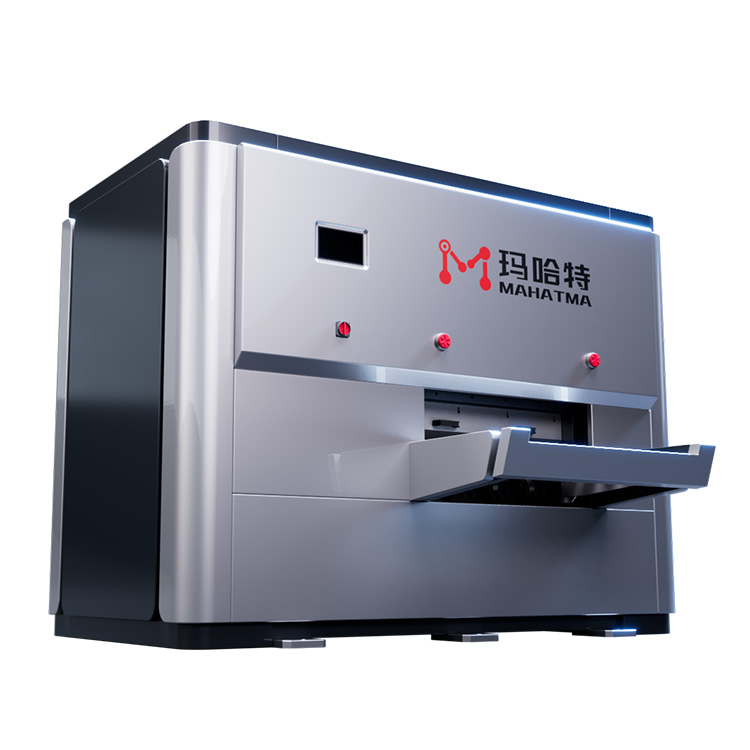

One of the main benefits of the sheet metal leveling machine for thick cutting parts is its ability to handle thicker sheets of metal. These machines can handle metal sheets that are up to 30mm thick, making them ideal for heavy-duty applications.

Another benefit of these machines is their precision. They are designed to level metal sheets to within a few microns of accuracy, ensuring that the metal is perfectly flat and straight. This level of precision is essential in industries such as shipbuilding, where even the slightest variation in flatness can compromise the structural integrity of the vessel.

The sheet metal leveling machine for thick cutting parts is also highly efficient. Because it is designed for thicker sheets of metal, it can process these sheets much more quickly and efficiently than traditional leveling machines. This means that manufacturers can produce more parts in less time, which can lead to significant cost savings.

In addition to its precision and efficiency, the sheet metal leveling machine for thick cutting parts is also highly versatile. It can be used to level a wide range of metals, including steel, aluminum, and copper. This makes it an ideal tool for manufacturers who work with a variety of materials.

The machine is also designed to be user-friendly, with intuitive controls and a simple interface. This means that operators can quickly learn how to use the machine, reducing the need for extensive training.

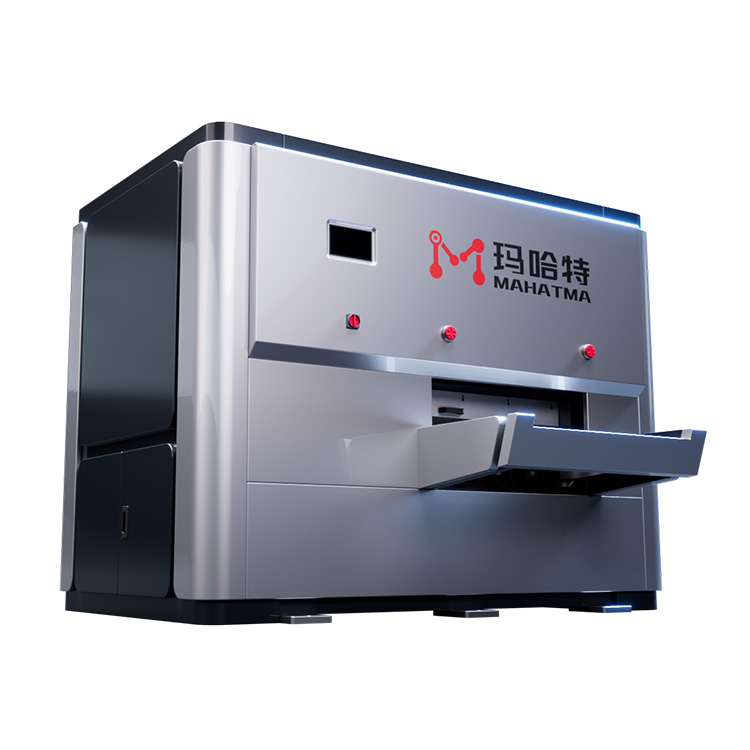

Overall, the sheet metal leveling machine for thick cutting parts is a critical tool for manufacturers who work with large, thick metal parts. Its ability to handle thicker metal sheets, precision, efficiency, versatility, and ease of use make it an ideal choice for industries such as shipbuilding, construction, and heavy machinery manufacturing. With this machine, manufacturers can level and flatten their metal parts quickly, accurately, and cost-effectively, improving the quality of their products and reducing waste.