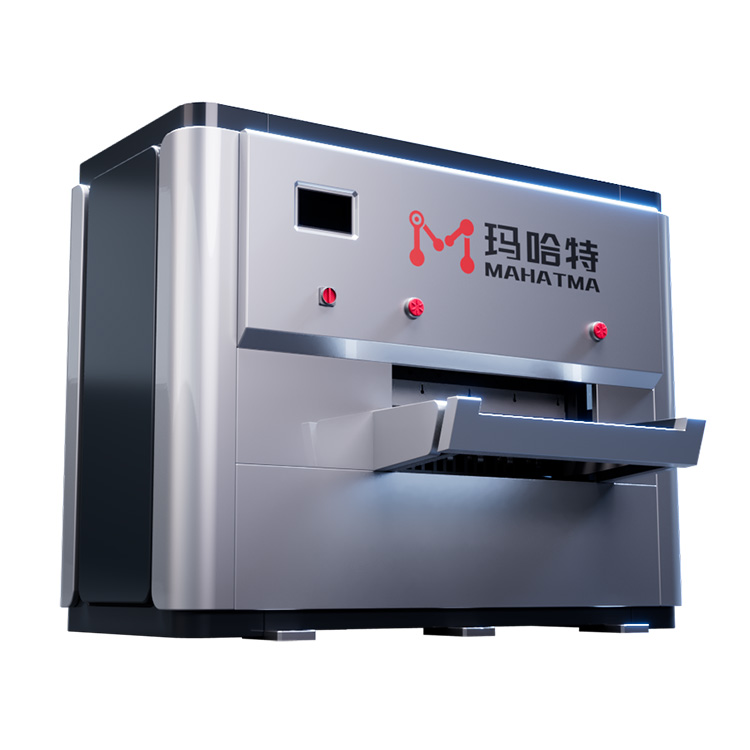

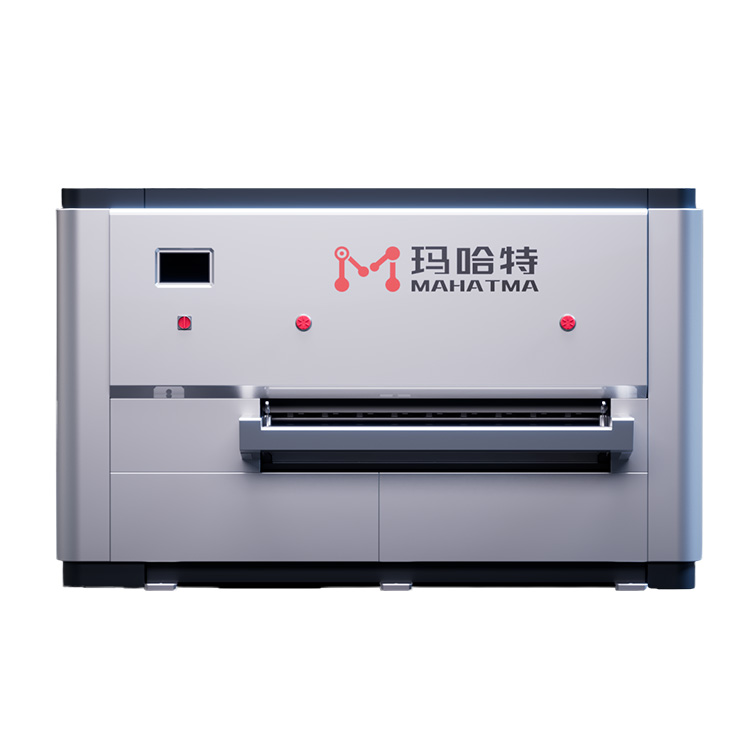

This machine adopts a Siemens PLC controller and is controlled by a Siemens frequency converter for operating speed. All machine movements are centrally controlled by the operating platform, with a touchscreen human-machine interface display screen and a simple and easy to understand operating panel. Emergency switches are installed at four prominent positions at the machine inlet and outlet to ensure safe operation! And equipped with a digital display to display the displacement, the operation is very simple and fast. In just a few seconds, high-precision and complex hardware components that typically require long-term manual leveling can be leveled.

| Sheet Metal Leveling Machine Parameter Table |

| Machine Model | MHTP40 | MHTP50 | MHTP60 |

| Roller Diameter | φ40mm | φ50mm | φ60mm |

| Roller Number | 23 | 23 | 23 |

| Speed | 0-10m/Min | 0-10m/Min | 0-10m/Min |

| Leveled Width | <1600mm | <2500mm | <2500mm |

| Rated Plate Thickness | 0.4~3.0mm | 0.8~5.0mm | 1.0~6.0mm |

| Maximum Thickness | 6mm | 8mm | 12mm |

| Shortest Workpiece | 75mm | 90mm | 100mm |

| Applicable Object | Laser cutting part, Punching & Perforated sheet |

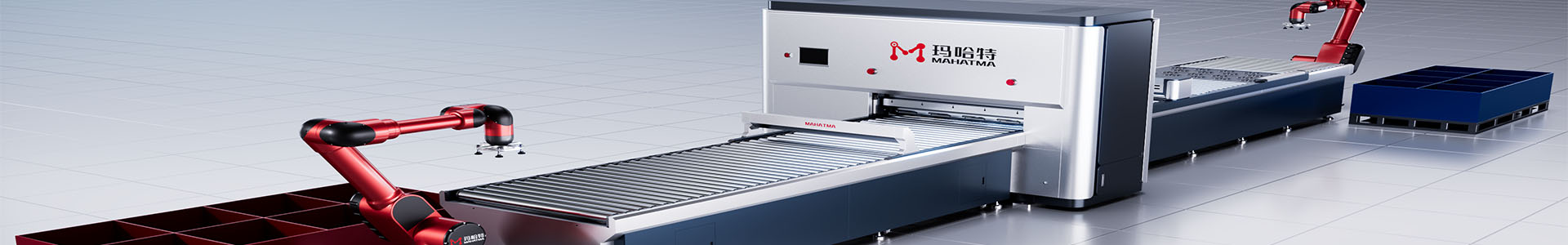

Sheet metal leveling machines are an essential tool for those involved in sheet metal processing. These machines are designed to flatten and level sheet metal, which is commonly used in a range of industries, including automotive, construction, and manufacturing. Sheet metal leveling machines are a valuable asset for any business involved in sheet metal processing, as they can improve the accuracy and efficiency of the production process.

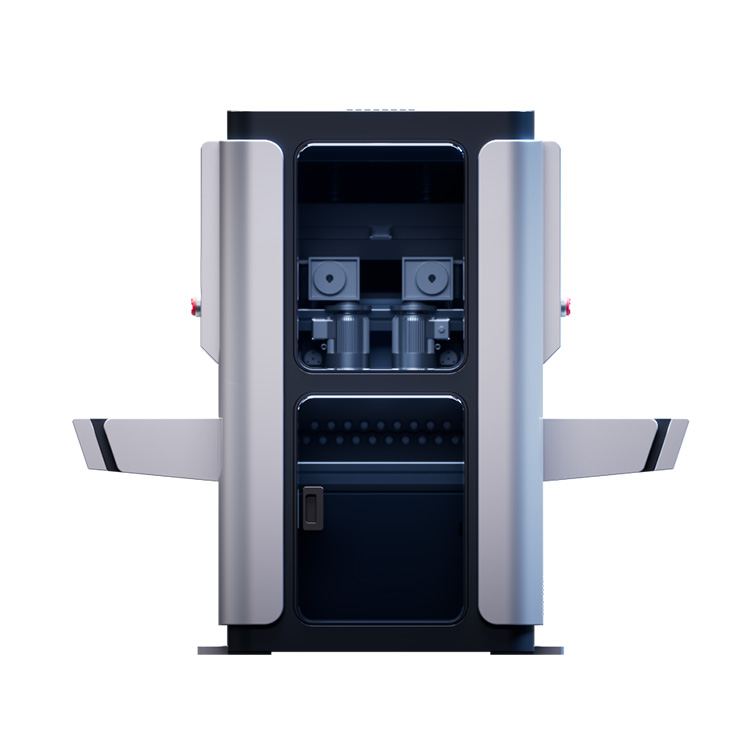

Sheet metal leveling machines are used to flatten and straighten sheet metal that may be warped or bent due to the manufacturing process or transportation. The machines use a series of rollers to apply pressure to the sheet metal, which helps to remove any kinks or bends in the material. The rollers are positioned at precise intervals along the length of the machine, which ensures that the metal is flattened and leveled evenly and accurately.

One of the key benefits of using a sheet metal leveling machine is that it can improve the quality of the finished product. Sheet metal that has been leveled using a machine is much more likely to meet the required specifications for size and shape. This can help to reduce the number of defective parts produced, which can save manufacturers time and money.

Another advantage of using a sheet metal leveling machine is that it can improve the efficiency of the production process. The machines are capable of leveling large volumes of sheet metal in a relatively short amount of time. This can help to increase the output of the manufacturing process, which can lead to higher profits for the manufacturer.

Sheet metal leveling machines are also very versatile machines. They can be used to level a wide range of different sheet metal thicknesses and sizes, including aluminum, copper, and steel. This makes them a valuable asset for manufacturers who work with a variety of different materials.

In addition to their versatility, sheet metal leveling machines are also very easy to operate. They require minimal training to use, and most models come with user-friendly controls that allow operators to adjust the tension and speed of the rollers. This makes it easy for manufacturers to incorporate these machines into their existing production processes.

Overall, sheet metal leveling machines are an essential piece of equipment for manufacturers who process sheet metal. They can improve the quality and efficiency of the production process, and they are capable of leveling a wide range of different sheet metal thicknesses and sizes. Whether you are a small business or a large manufacturer, investing in a sheet metal leveling machine can help you to produce high-quality parts that meet the required specifications.