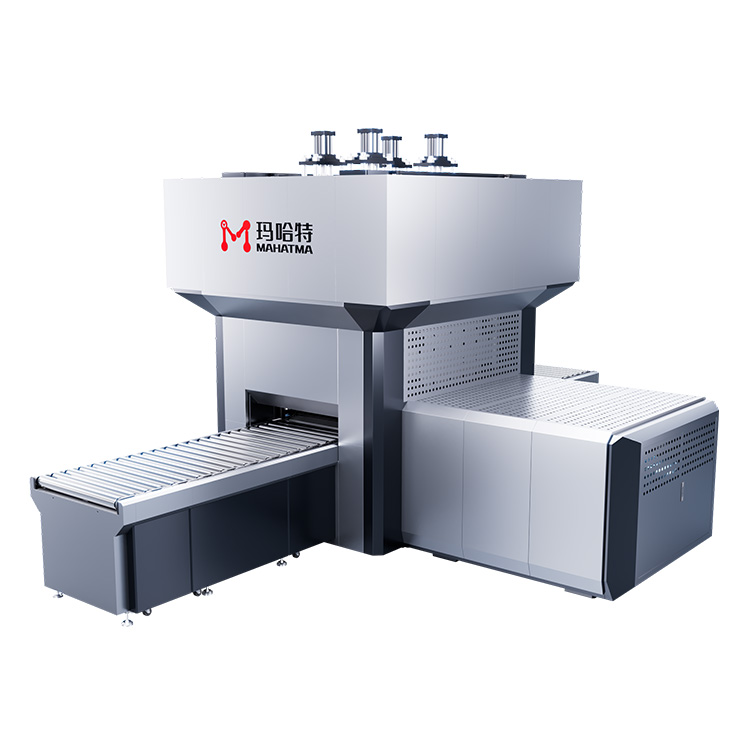

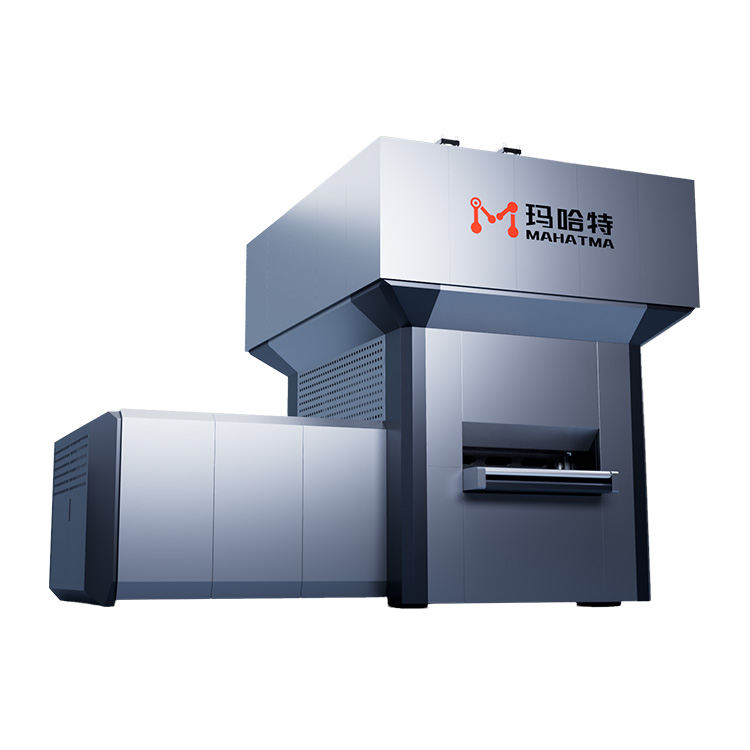

This leveling machine adopts a Siemens PLC controller and is controlled by a Siemens frequency converter for operating speed. All leveling machine movements are centrally controlled by the operating platform, with a touchscreen human-leveling machine interface display screen and a simple and easy to understand operating panel. Emergency switches are installed at four prominent positions at the leveling machine inlet and outlet to ensure safe operation! And equipped with a digital display to display the displacement, the operation is very simple and fast. In just a few seconds, high-precision and complex hardware components that typically require long-term manual leveling can be leveled.

Product Features

★ The roller can be fully automatically extracted (convenient for cleaning the roller)

★ Automatic quantity calculation (can be connected to various MRP and ERP systems for control, automatic setting and monitoring of equipment startup time, effective working time, and automatic counting of processed parts)

★ Full support (the entire roller is fully supported, with strong structural force)

★ Automatic monitoring function (convenient for monitoring equipment and production status at any time, convenient for repair and maintenance)

★ Wide support shaft (improves the operating rigidity of the leveling roller and reduces indentation on a larger range)

★ Remote control function (for customers in remote areas, our engineers can help customers solve problems such as not being able to adjust leveling machines or equipment malfunctions at any time)

★ Optoelectronic protection (to avoid unnecessary safety hazards caused by personnel or workpieces entering the equipment by mistake)

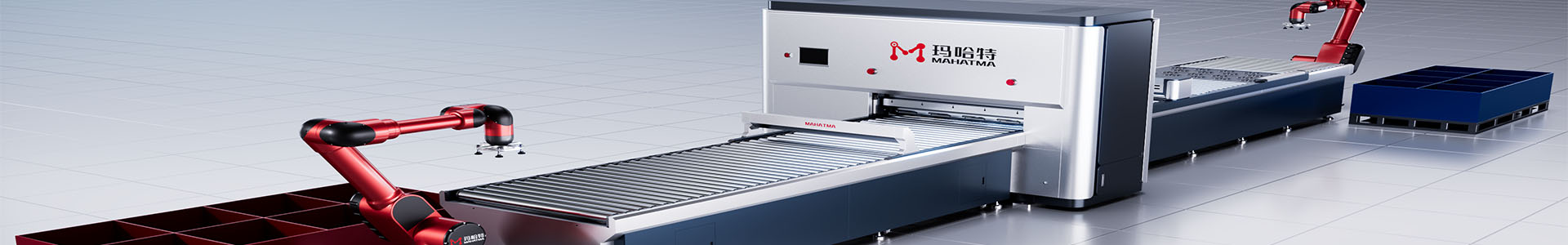

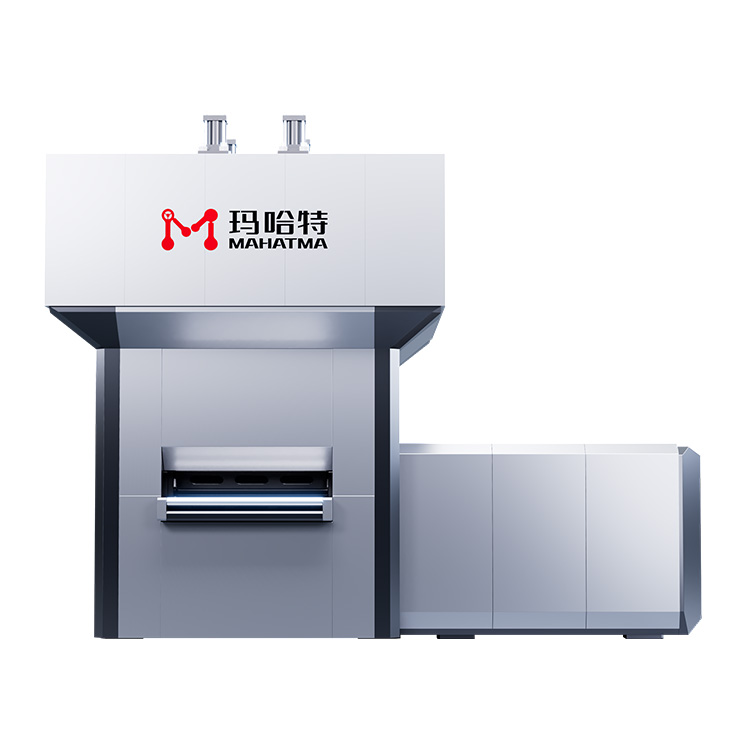

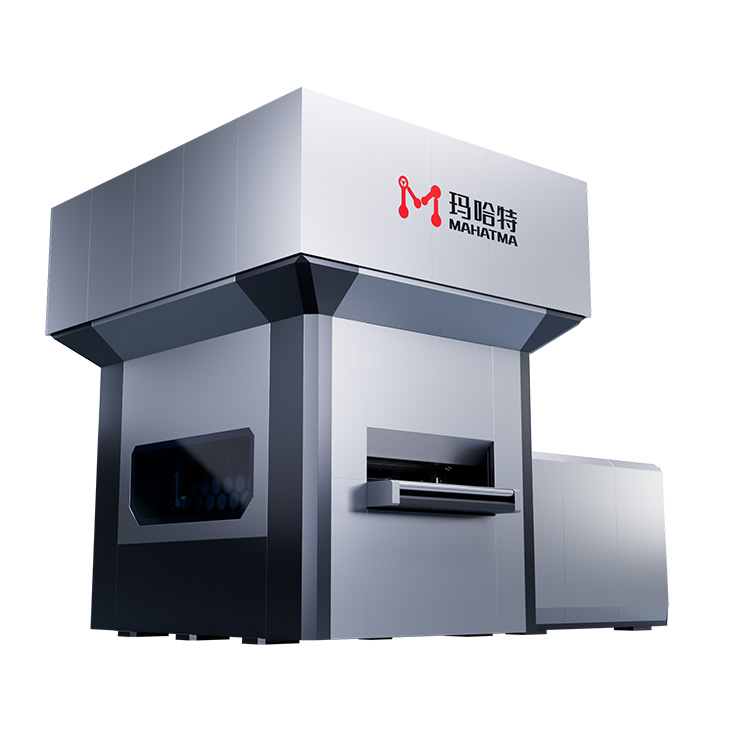

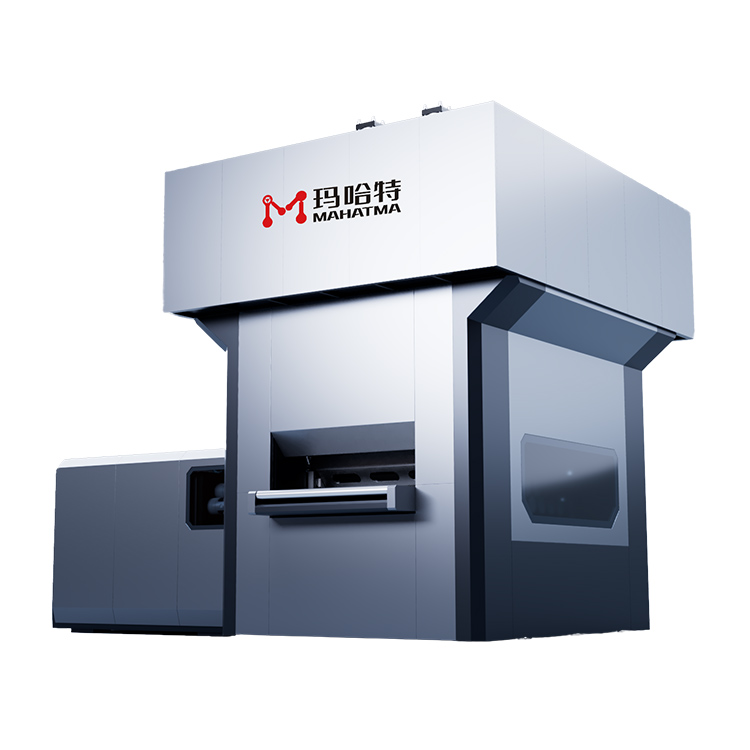

★ BMW paint (using high-end BMW baking paint, the whole leveling machine is stable, high-end, and luxurious)

★ Automatic flatness detection (automatic scanning accuracy detection) (optional)

★ Unmanned and fully automatic adjustment of the entire line (optional)

1. Intelligent operating system

New style, powerful dynamic performance and stability, improving software operation smoothness; Integrated fast intelligent leveling mode;

2. MHTP series high-precision leveling leveling machine

Independent intellectual property rights, multiple patented technologies, ultra-high efficiency leveling, intelligent control;

3. All leveling machine tool self-lubricating system

High intelligence, high integration, maintenance free, one click setting of low oil pressure alarm, no oil shutdown, to avoid machine wear caused by delayed lubrication;

4. Remote cloud control system

Can achieve remote monitoring of equipment operation status, fault inquiry, fault diagnosis, etc., and real-time cloud monitoring of equipment;

5. Independently developed gearbox

Gear universal joint transmission, faster acceleration and speed, better rigidity and impact resistance;

6. Hollow structure leveling machine tool

The main body of the leveling machine tool has no heating area and is permanently used without thermal deformation. The leveling machine body is stable and reliable, ensuring long-term stability of leveling accuracy.

Sheet metal leveling machines are an important tool for fabricating and manufacturing industries. They are used to straighten and level sheets of metal, making them easier to work with and reducing waste. However, most traditional sheet metal leveling machines are designed for larger sheets, and they are not suitable for small, thin parts. This is where the sheet metal leveling machine for small thin parts comes in.

The sheet metal leveling machine for small thin parts is a specialized tool that is designed to handle sheets of metal that are too small or too thin for traditional leveling machines. These machines are typically used in industries such as electronics, medical devices, and precision manufacturing, where small, thin metal parts are frequently used.

These machines work by feeding the sheet of metal through a series of rollers that apply pressure to the metal, flattening and leveling it out. The rollers are designed to be adjustable, allowing the operator to adjust the pressure and spacing between the rollers to achieve the desired level of flatness.

One of the key benefits of the sheet metal leveling machine for small thin parts is its precision. These machines are designed to handle sheets of metal that are as thin as 0.1mm, and they can level the metal to within a few microns of accuracy. This level of precision is essential in industries such as electronics and medical devices, where even the slightest variation in thickness or flatness can cause problems.

Another benefit of these machines is their efficiency. Because they are designed specifically for small, thin parts, they can process these parts much more quickly and efficiently than traditional leveling machines. This means that manufacturers can produce more parts in less time, which can lead to significant cost savings.

The sheet metal leveling machine for small thin parts is also highly versatile. It can be used to level a wide range of metals, including aluminum, copper, stainless steel, and titanium. This makes it an ideal tool for manufacturers who work with a variety of materials.

In addition to its precision, efficiency, and versatility, the sheet metal leveling machine for small thin parts is also easy to use. It is designed to be user-friendly, with intuitive controls and a simple interface. This means that operators can quickly learn how to use the machine, reducing the need for extensive training.

The sheet metal leveling machine for small thin parts is an essential tool for manufacturers who work with small, thin metal parts. Its precision, efficiency, versatility, and ease of use make it an ideal choice for a wide range of industries, from electronics to medical devices to precision manufacturing. With this machine, manufacturers can level and flatten their metal parts quickly, accurately, and cost-effectively, improving the quality of their products and reducing waste.