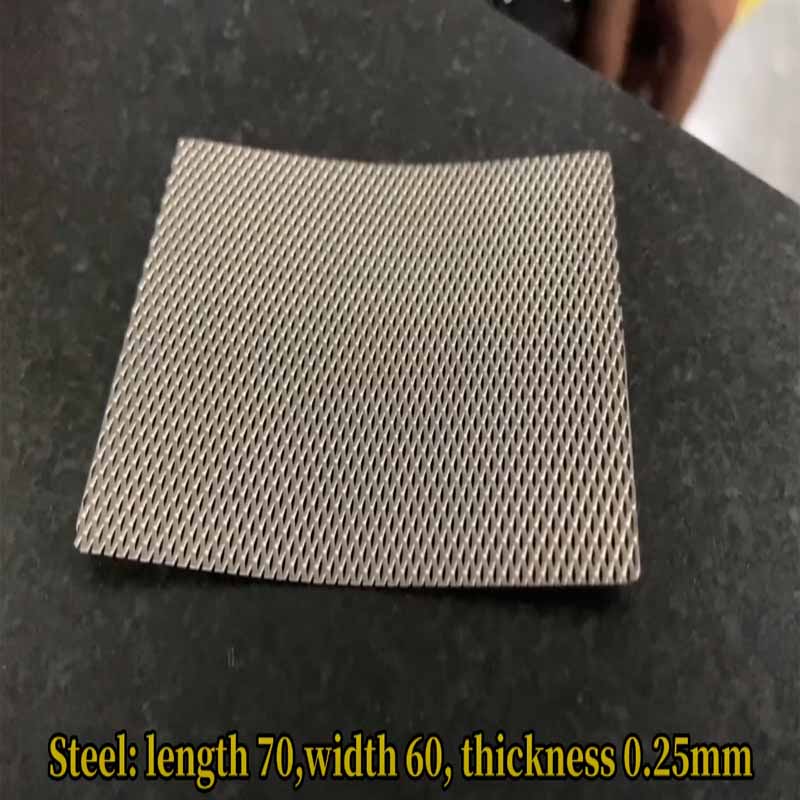

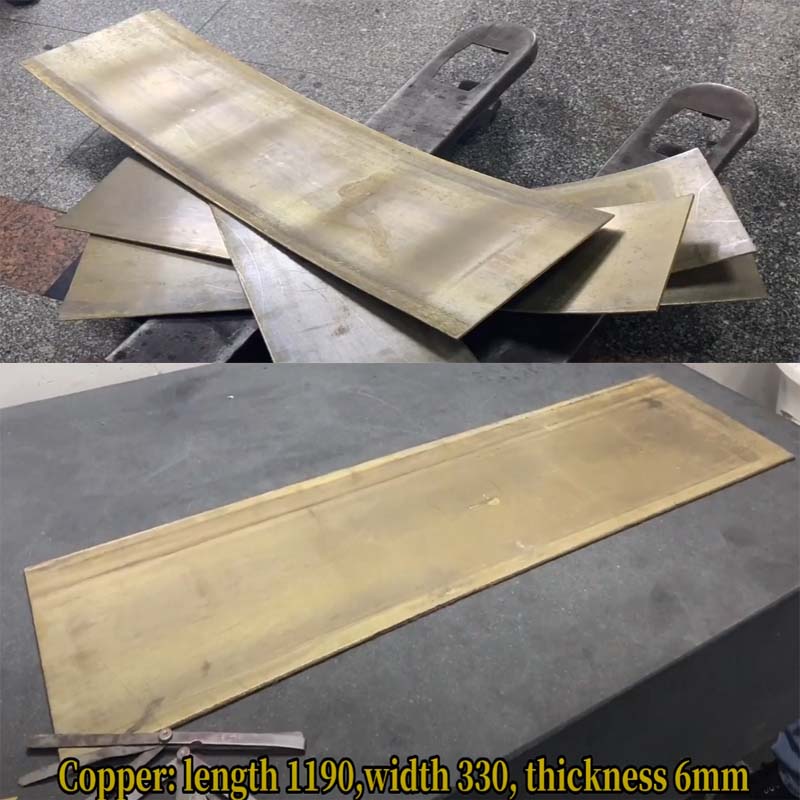

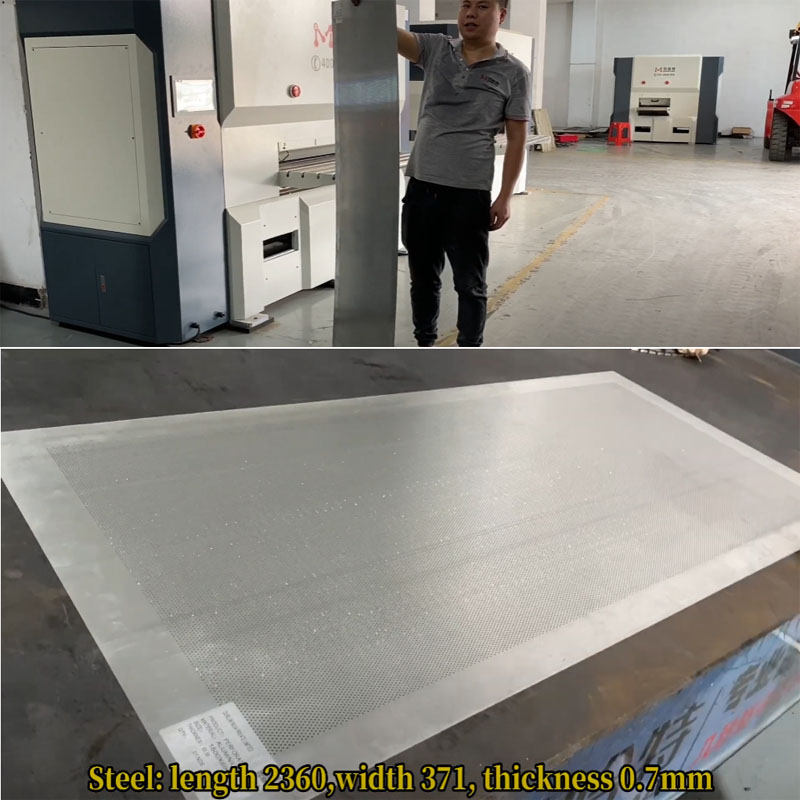

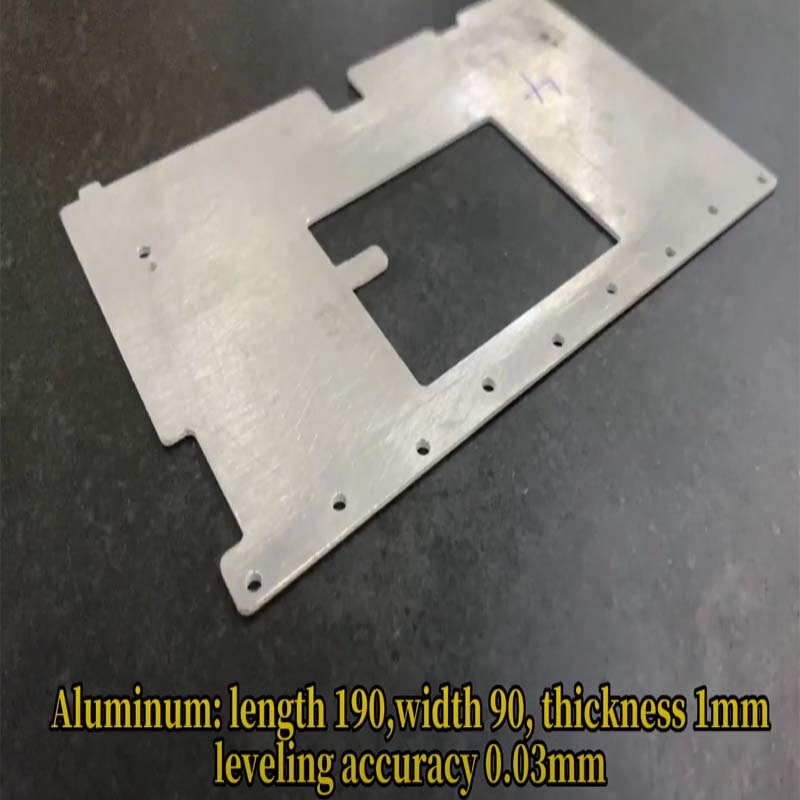

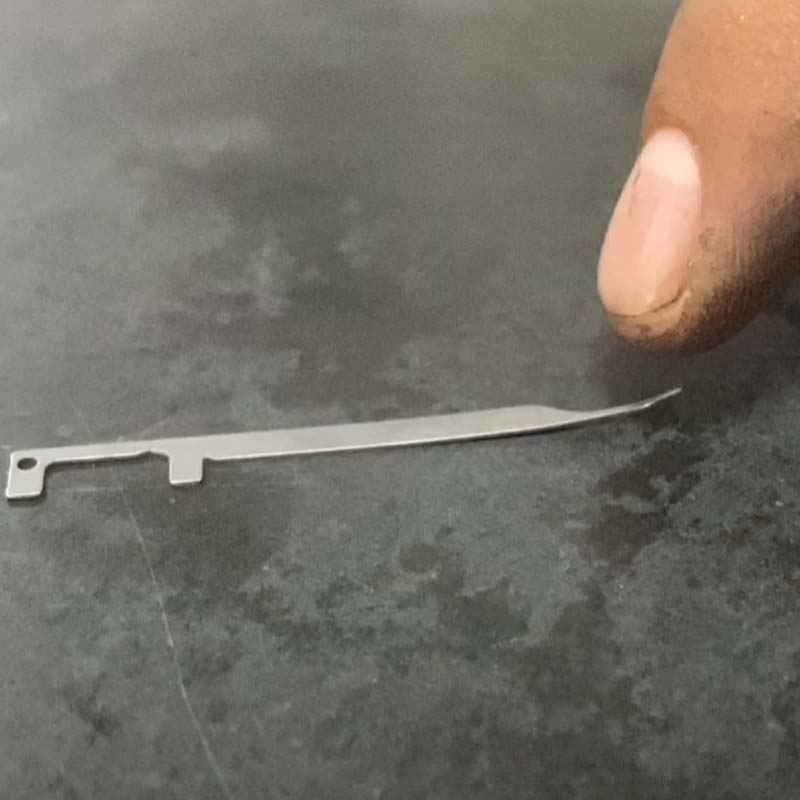

Thickness: 0.5m-2.0mm

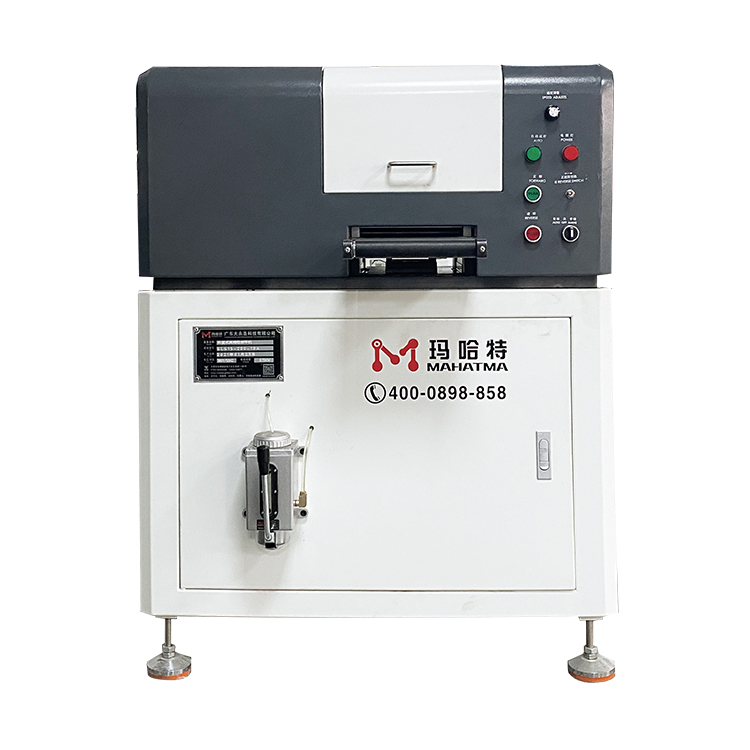

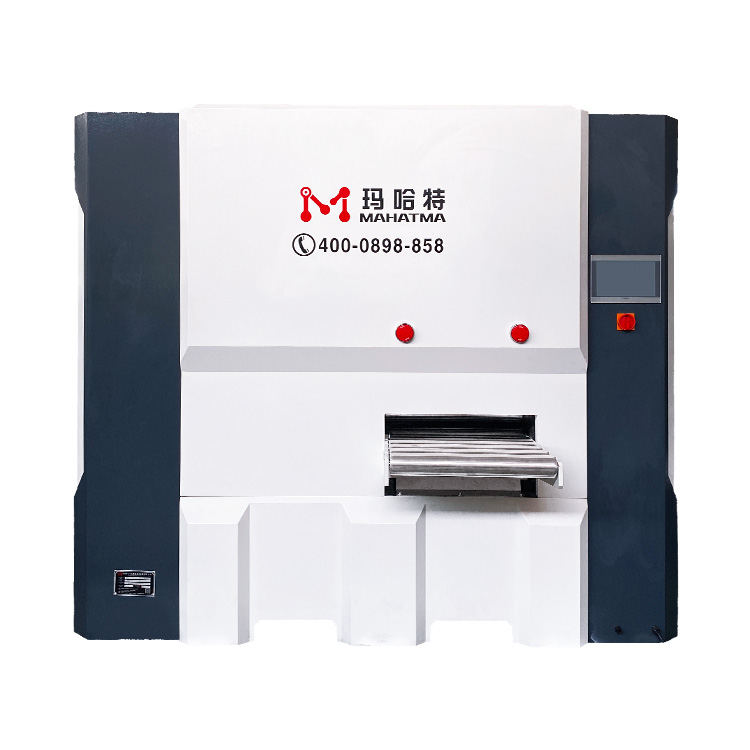

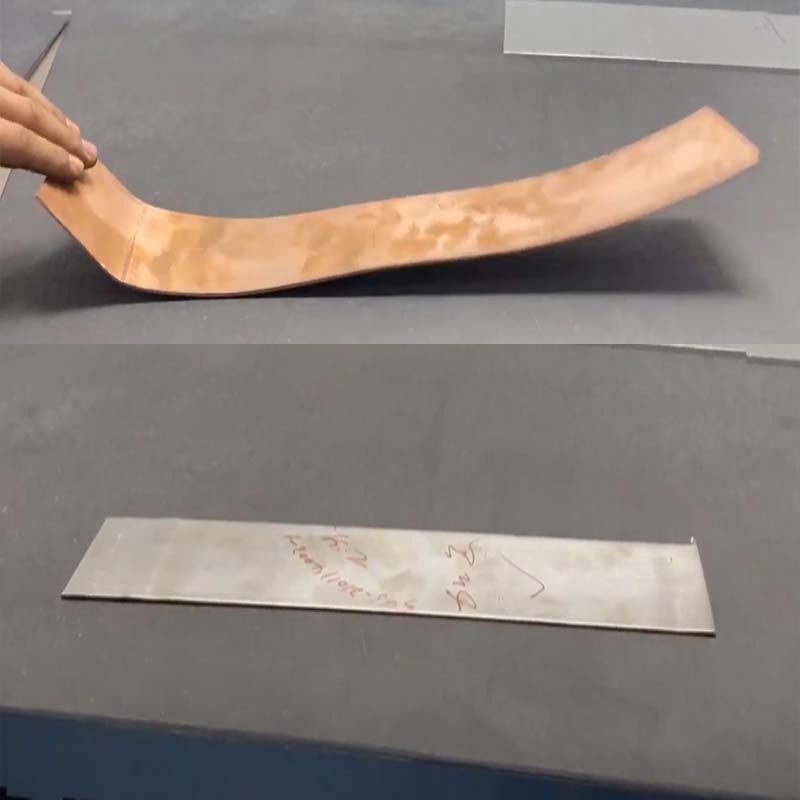

Semi-automatic Part Leveing Machine achieves leveling effect by using multiple sets of rollers for rolling and leveling. Four layers high-precision leveling machine adopts a supporting roller structure between the upper and lower rows of leveling work rolls and the supporting bearings (wheels), forming a total of four roller groups with two upper and two lower layers; The leveling roller has uniform force distribution, good structural rigidity, small bending deformation of the work roller, high leveling accuracy, and harmonic attenuation straightening of the stroke. It fundamentally solves the common problems of unevenness, easy roll imprint indentation, workpiece collapse, sickle bending, etc. in ordinary leveling, improves the accuracy of sheet metal correction, and has a wide range of applications.

Send Email

More

Menu

- Home

- Products

- Sheet Metal Leveling Machine

- Sheet Metal Flattening Machine

- Sheet Metal Straightening Machine

- Semi-Automatic Leveling Machine

- Cut to length

- Laser Cutting Blanking

- Videos

- Sheet Metal Leveling Machine

- Sheet Metal Flattening Machine

- Sheet metal straightening machine

- Semi-automatic leveling machine

- MAHATMA Factory

- Case

- Sheet Metal Leveling Machine

- Sheet Metal Flattening Machine

- Sheet metal straightening machine

- Semi-automatic leveling machine

- News

- Company News

- Product News

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

- Factroy

- Contact Us

Search